Imagine being able to build or repair electric vehicles using recycled materials. It’s an exciting concept that not only benefits the environment but also contributes to the advancement of sustainable transportation. This article explores the possibility of utilizing recycled materials for the construction and maintenance of electric vehicles. From exploring the potential benefits to addressing the challenges and limitations, we will delve into the world of eco-friendly electric vehicle innovation. So, let’s embark on this journey together and discover the potential of recycled materials in the world of electric vehicles.

Benefits of Using Recycled Materials

Reduced Environmental Impact

Using recycled materials in the construction of electric vehicles can significantly reduce the environmental impact associated with traditional manufacturing processes. When we recycle materials like aluminum, steel, and plastic, we conserve natural resources and minimize the need for mining or extracting raw materials. This reduction in resource consumption helps in preserving ecosystems and reducing energy consumption.

Lower Cost

Another major benefit of using recycled materials in electric vehicles is the potential for cost savings. Recycling materials can be a more cost-effective option compared to sourcing and processing new raw materials. By incorporating recycled materials, manufacturers can reduce production costs and pass those savings on to consumers. This, in turn, can make electric vehicles more affordable and accessible to a wider range of people, ultimately accelerating the transition to cleaner transportation.

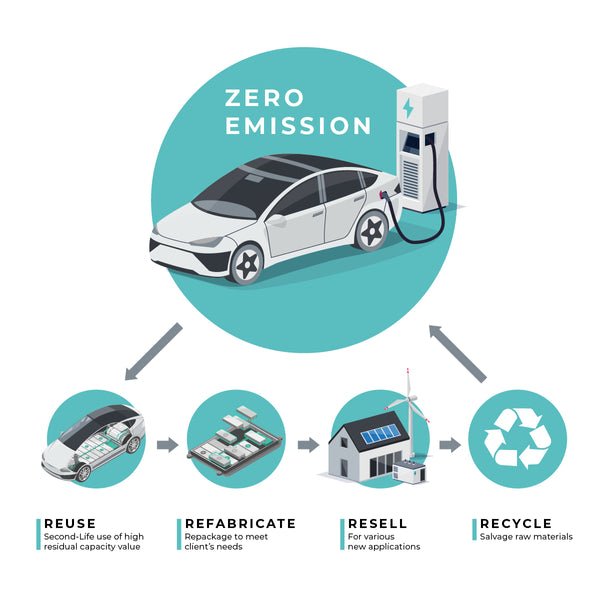

Promotion of Circular Economy

Using recycled materials promotes the concept of a circular economy, where resources are kept in a continuous loop of use and reuse. By utilizing recycled materials in electric vehicle construction, we are diverting waste from landfills and reducing the need for new production. This efficient use of materials and resources aligns with the principles of sustainability and helps create a more resilient and environmentally conscious society.

Available Recycled Materials for Electric Vehicle Construction

Recycled Aluminum

Aluminum is an ideal material for recycling due to its infinite recyclability. By recycling aluminum, we can reduce energy consumption by up to 95% compared to producing virgin aluminum. Recycled aluminum can be used in various components of electric vehicles, including structural sections, body panels, and heat exchangers. Its lightweight nature also contributes to improving the overall energy efficiency and performance of electric vehicles.

Recycled High-Strength Steel

High-strength steel is known for its durability and ability to withstand high stress and impact. It is commonly used in the construction of electric vehicle frames, chassis, and safety components. By using recycled high-strength steel, we can minimize the need for mining iron ore and reduce carbon dioxide emissions by up to 58%. Recycling steel also generates significant energy savings, making it a sustainable choice for electric vehicle manufacturers.

Recycled Plastic

Plastic is a versatile material used in a wide range of applications, including automotive components. By recycling plastic, we can reduce the demand for new plastic production that contributes to pollution and landfill waste. Recycled plastic can be used in the manufacturing of electric vehicle interior trim, battery casings, and exterior body panels. Utilizing recycled plastic not only conserves resources but also helps in reducing carbon emissions associated with plastic production.

Suitability of Recycled Materials for Electric Vehicles

Strength and Durability

One crucial factor in using recycled materials for electric vehicles is ensuring their strength and durability. These vehicles need to withstand various road conditions and meet safety standards. Both recycled aluminum and high-strength steel have proven to be suitable materials in terms of strength and durability. Through proper inspection and testing, recycled materials can be evaluated for their suitability and safety in electric vehicle construction.

Compatibility with Electric Vehicle Components

Recycled materials must be compatible with the components used in electric vehicles. They should possess the required properties and characteristics to function effectively in various parts and systems. For example, recycled plastics need to have the appropriate heat resistance and stability to be used in battery casings. Manufacturers need to carefully evaluate the compatibility of recycled materials with electric vehicle components to ensure optimal performance and reliability.

Safety Considerations

Safety is of utmost importance in the design and construction of electric vehicles. When using recycled materials, it is important to consider any potential safety implications. Manufacturers should conduct thorough testing and certification to ensure that the recycled materials meet the required safety standards. By prioritizing safety considerations, manufacturers can confidently incorporate recycled materials without compromising the overall safety of electric vehicles.

Examples of Electric Vehicle Components that Can Be Made with Recycled Materials

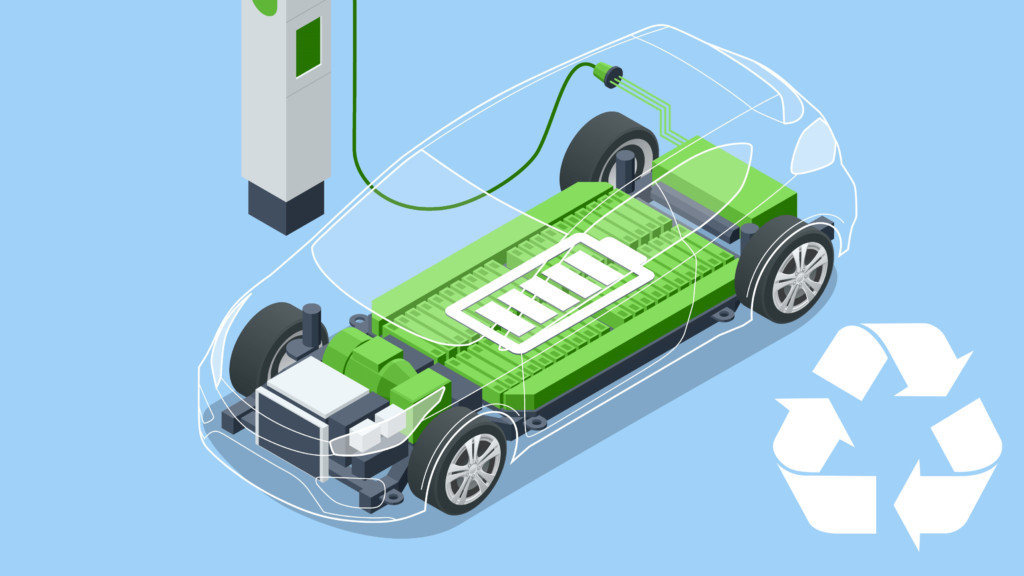

Battery Casings

Battery casings protect the crucial components of an electric vehicle’s battery pack. Using recycled plastic or aluminum can be an excellent choice for manufacturing battery casings. Recycled plastic provides lightweight and durable protection, while recycled aluminum offers strength and excellent heat dissipation properties.

Interior Trim

Recycled plastic can be used for manufacturing interior trim components, such as door panels, dashboard components, and seat covers. By utilizing recycled plastic, manufacturers can reduce the environmental impact of these components while still providing a high-quality and aesthetically pleasing interior for electric vehicle owners.

Exterior Body Panels

Recycled aluminum and high-strength steel are ideal materials for producing exterior body panels. These materials offer strength, durability, and corrosion resistance, ensuring the longevity of the vehicle’s exterior while minimizing the environmental impact associated with traditional manufacturing processes.

Challenges in Using Recycled Materials for Electric Vehicles

Consistency and Quality Control

One of the challenges in using recycled materials for electric vehicles is maintaining consistency and quality control. Recycled materials can vary in composition and quality, which may affect their suitability for specific applications. To overcome this challenge, manufacturers need to establish robust quality control measures, including thorough material testing and evaluation, to ensure consistency and reliability in the use of recycled materials.

Availability and Sourcing

The availability and sourcing of recycled materials can pose challenges for electric vehicle manufacturers. It is important to establish reliable supply chains and partnerships with recycling facilities to ensure a consistent and sufficient supply of recycled materials. This may involve investing in infrastructure and logistics to facilitate the efficient sourcing and transportation of recycled materials to the manufacturing facilities.

Regulatory Requirements

Manufacturers also need to navigate regulatory requirements and standards when using recycled materials in electric vehicles. These requirements may vary across different regions and jurisdictions, adding complexity to the adoption of recycled materials. To address this challenge, collaboration between regulatory bodies and manufacturers is essential to establish clear guidelines and standards that promote the responsible use of recycled materials in electric vehicle construction.

Strategies to Implement the Use of Recycled Materials in Electric Vehicle Construction

Partnerships with Recycling Facilities

Establishing partnerships with recycling facilities can facilitate the reliable and efficient sourcing of recycled materials. Collaboration between electric vehicle manufacturers and recycling facilities can help streamline the recycling process, ensuring a consistent supply of high-quality recycled materials for electric vehicle construction.

Research and Development Initiatives

Investing in research and development initiatives can drive innovation in the use of recycled materials for electric vehicles. By conducting extensive research, manufacturers can explore new technologies and techniques to enhance the quality and suitability of recycled materials. This can lead to the development of advanced recycling technologies and the discovery of new materials that meet the specific requirements of electric vehicle construction.

Incentives for Manufacturers

To encourage the use of recycled materials, governments and regulatory bodies can provide incentives for manufacturers. These incentives can include tax breaks, grants, or subsidies that help offset the initial costs associated with implementing recycled materials in electric vehicle production. By providing financial support, governments can accelerate the adoption of sustainable practices in the automotive industry.

Case Studies of Electric Vehicle Companies Using Recycled Materials

Company A: Incorporating Recycled Plastics in Dashboard Components

Company A, a leading electric vehicle manufacturer, has successfully incorporated recycled plastics in the production of dashboard components. Through partnerships with recycling facilities, they have sourced recycled plastics that meet their stringent quality and safety requirements. By utilizing recycled plastics, they have managed to reduce their environmental footprint while maintaining the high-quality standards their customers expect.

Company B: Using Recycled Steel in Battery Pack Enclosures

Company B recognizes the importance of using recycled materials in electric vehicle construction. They have implemented the use of recycled high-strength steel for battery pack enclosures. This has not only reduced their reliance on virgin steel but also resulted in significant energy savings and carbon emissions reduction. Company B’s commitment to sustainability showcases the potential and benefits of incorporating recycled materials in electric vehicle manufacturing.

Company C: Utilizing Recycled Aluminum for Lightweight Body Frame

Company C takes advantage of recycled aluminum for the construction of lightweight body frames. By sourcing recycled aluminum, they contribute to the reduction of energy consumption and carbon emissions associated with traditional aluminum production. This approach not only enhances the fuel efficiency of their electric vehicles but also aligns with their commitment to environmental stewardship.

Steps for DIY Electric Vehicle Enthusiasts to Use Recycled Materials

Research and Identify Suitable Materials

DIY electric vehicle enthusiasts should start by researching and identifying suitable recycled materials for their projects. This may involve studying the properties and characteristics of different recycled materials such as aluminum, steel, and plastics. By considering factors such as strength, durability, and compatibility, enthusiasts can select the most suitable materials for their specific electric vehicle designs.

Source Recycled Materials

Once suitable materials have been identified, enthusiasts can explore various sources for obtaining recycled materials. This may involve contacting local recycling facilities, scrap yards, or online marketplaces specializing in recycled materials. It’s important to ensure that the sourced materials meet the required standards and specifications for electric vehicle construction.

Adapt Designs and Construction Techniques

Designing and constructing an electric vehicle with recycled materials often requires adaptation and innovation. DIY enthusiasts should modify their designs and construction techniques to accommodate the unique properties and limitations of recycled materials. This may involve consulting experts or experienced individuals who have successfully built electric vehicles using recycled materials.

Considerations for Repairing Electric Vehicles with Recycled Materials

Determine Compatibility of Materials with Original Components

When repairing electric vehicles using recycled materials, it is crucial to ensure compatibility with the original components. Recycled materials should possess properties that closely match those of the original materials to ensure compatibility and optimal performance. Thorough assessment and testing should be conducted to determine the suitability of recycled materials for specific repair jobs.

Ensure Proper Testing and Validation

To ensure the safety and reliability of repaired electric vehicles, proper testing and validation of recycled materials are essential. The repaired components should undergo rigorous testing to verify their performance, durability, and safety. This will help identify any potential issues and ensure that the repaired vehicle meets or exceeds industry standards.

Follow Manufacturer Guidelines

When repairing electric vehicles with recycled materials, it is important to follow the guidelines provided by the vehicle’s original manufacturer. These guidelines may include instructions specific to repairing components and systems with recycled materials. Adhering to these guidelines ensures that the repaired vehicle maintains its warranty, performance, and safety standards.

Future Outlook and Potential for Recycled Materials in Electric Vehicle Industry

Advancements in Material Recycling Technologies

The future of the electric vehicle industry holds great potential for advancements in material recycling technologies. As recycling technologies continue to evolve, the quality and availability of recycled materials will improve. Innovations in recycling processes, such as advanced sorting techniques and chemical recycling, can further enhance the viability of recycled materials for electric vehicle construction.

Collaboration between Automotive and Recycling Sectors

Collaboration between the automotive and recycling sectors will play a significant role in promoting the use of recycled materials in electric vehicles. By working together, these sectors can establish efficient supply chains, share knowledge and resources, and develop standardized practices for the responsible use of recycled materials. This collaboration can drive the transformation of the automotive industry towards a more sustainable and circular economy.

Increasing Consumer Demand for Sustainable Vehicles

Consumer demand for sustainable vehicles is on the rise, creating a market opportunity for electric vehicle manufacturers that incorporate recycled materials. As eco-consciousness grows, consumers are actively seeking out products with lower environmental impact. By prioritizing the use of recycled materials, electric vehicle manufacturers can attract environmentally aware consumers, boosting sales and driving industry-wide change.

In conclusion, the use of recycled materials in electric vehicle construction offers various benefits, including reduced environmental impact, lower costs, and the promotion of a sustainable circular economy. Recycled materials such as aluminum, high-strength steel, and plastic are suitable for manufacturing a wide range of electric vehicle components. However, challenges such as consistency, availability, and regulatory requirements need to be addressed. Strategies such as partnerships, research and development initiatives, and incentives can help overcome these challenges and foster the adoption of recycled materials in the electric vehicle industry. With proactive efforts from manufacturers, case studies showcasing successful implementation, and consideration for DIY enthusiasts and repair procedures, the future outlook for recycled materials in the electric vehicle industry is promising. Advancements in recycling technologies, collaboration between sectors, and increasing consumer demand for sustainable vehicles will drive the continued integration of recycled materials, paving the way for a greener and more sustainable transportation sector.