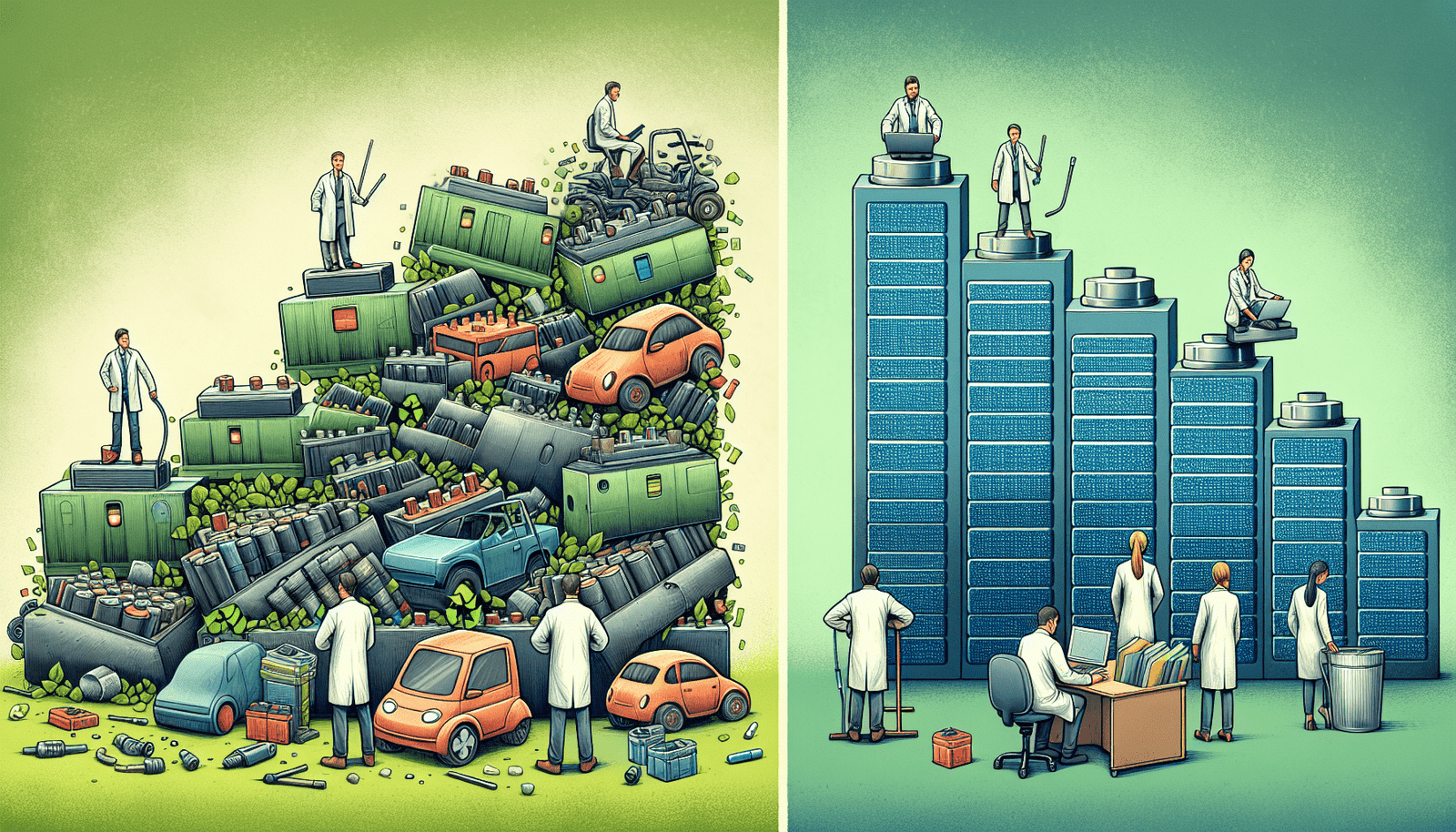

In today’s push towards sustainability, the recycling and reusing of electric vehicle (EV) batteries has become a crucial topic. With the rise in popularity of EVs, there is an inevitable increase in the number of discarded batteries. However, rather than simply disposing of them, innovative methods are being developed to repurpose these batteries and minimize waste. From transforming them into energy storage systems for renewable sources to repackaging them for use in other vehicles, the recycling and reusing of electric vehicle batteries presents a promising solution for the future.

Recycling Process

Collection of Batteries

The first step in the recycling process is the collection of batteries. This is a crucial stage as it ensures that the batteries are diverted from ending up in landfill and instead are sent for recycling. There are different ways of collecting batteries, including drop-off points at recycling centers, collection events, and even mail-back programs. It is important for consumers and businesses to be aware of these collection methods and actively participate in battery recycling.

Battery Sorting

Once the batteries have been collected, the next step is battery sorting. This involves categorizing the batteries based on their chemistry and type. Different types of batteries have different recycling processes, so it is important to separate them accordingly. Additionally, sorting helps to identify any potentially hazardous materials that may require special handling during the recycling process.

Battery Shredding

After the batteries have been sorted, they are typically shredded into small pieces. Battery shredding helps to increase surface area and facilitate subsequent processing steps. It also helps to separate different battery components from each other, such as the casing, electrodes, and electrolyte.

Chemical Processing

Chemical processing is a crucial step in the battery recycling process. During this stage, the shredded batteries are subjected to different chemical treatments to extract valuable materials. For example, for lithium-ion batteries, the electrolyte is neutralized and the metals are dissolved, while organic solvents can be recovered through distillation. This process allows for the recovery of valuable materials such as lithium, cobalt, and nickel.

Metallurgical Processing

Metallurgical processing involves further separation and purification of the recovered metals. The metals recovered from the chemical processing stage are typically in the form of compounds or alloys. Metallurgical processes such as smelting, refining, and alloying are used to produce high-purity metals that can be used in various industries. This ensures that the recovered materials can be reused effectively.

Recovery and Reuse of Materials

Extraction of Lithium

Lithium is a valuable and essential component in electric vehicle batteries. After it has been recovered from the recycling process, it can be extracted and purified for reuse. The extraction of lithium involves several steps, including solvent extraction and electrolysis. Once extracted, lithium can be used in the production of new batteries or sold to manufacturers who use it as a raw material.

Recovery of Cobalt

Cobalt is another valuable material found in electric vehicle batteries. It is used in the cathode of lithium-ion batteries and plays a crucial role in their performance. The recovery of cobalt involves various processes, including precipitation, filtration, and solvent extraction. Once recovered, cobalt can be reused in battery manufacturing or sold to other industries that have a demand for this precious metal.

Reuse of Battery Cells

In addition to extracting valuable materials, battery recycling also focuses on reusing battery cells. Reusing battery cells involves testing and refurbishing them to ensure that they are still in good condition. These cells can then be used in second-life applications, such as battery energy storage systems or off-grid energy storage. By giving battery cells a second life, we can reduce waste and extend their usefulness.

Recovery of Other Materials

Apart from lithium and cobalt, electric vehicle batteries also contain other materials that can be recovered and reused. These materials include nickel, manganese, aluminum, and graphite. Each of these materials has its own recycling process and can be used in different applications. By recovering and reusing these materials, we can further reduce the environmental impact of electric vehicle battery production and disposal.

Battery Second Life

Battery Energy Storage Systems (BESS)

One of the primary applications for reused battery cells is in battery energy storage systems (BESS). These systems allow for the storage of excess energy during periods of low demand, which can then be used during peak demand periods. By utilizing second-life battery cells in BESS, we can make use of batteries that still have a significant amount of capacity left. This not only reduces the need for new battery production but also helps to stabilize the grid and support renewable energy integration.

Off-Grid Energy Storage

In areas without access to a reliable electricity grid, off-grid energy storage can provide a sustainable solution. Reused battery cells can be combined with renewable energy sources, such as solar panels or wind turbines, to store and utilize energy when needed. This allows individuals and communities to have access to clean, reliable energy, even in remote locations.

Renewable Energy Integration

Renewable energy sources, such as wind and solar, are intermittent in nature. The ability to store excess energy and release it when needed is crucial for the efficient integration of renewable energy into the grid. Second-life battery cells can play a significant role in this regard by providing a cost-effective and sustainable energy storage solution.

Grid Stabilization

The power grid experiences fluctuations in energy demand throughout the day. Reused battery cells can be used to provide additional power during peak demand periods, helping to stabilize the grid and prevent blackouts or brownouts. By using second-life batteries for grid stabilization, we can reduce the strain on the grid and ensure a reliable supply of electricity.

Recycling Challenges

Battery Design and Composition

Battery recycling faces challenges due to the diverse design and composition of batteries used in electric vehicles. There are various types of batteries, including lithium-ion, nickel-metal hydride, and solid-state batteries, each with different chemistries and structures. This variation makes it necessary for recycling facilities to develop specialized processes for each battery type.

Collection and Transport Infrastructure

Another challenge is the availability of an efficient collection and transport infrastructure for used electric vehicle batteries. Establishing a well-coordinated system that facilitates the safe and convenient collection of batteries from various sources is crucial. Additionally, transportation methods need to be optimized to ensure the secure and efficient transportation of batteries to recycling facilities.

Safety and Environmental Concerns

Battery recycling also brings about safety and environmental concerns. Batteries contain hazardous materials that can pose risks if not handled properly. Recycling facilities must have robust safety measures in place to protect workers and prevent environmental contamination. Proper disposal of harmful by-products is also essential to ensure minimal impact on the environment.

Limited Recycling Facilities

The limited number of recycling facilities is a significant challenge in the recycling process. As the demand for electric vehicles continues to grow, the capacity of existing recycling facilities may not be sufficient. It is crucial to invest in the expansion of recycling infrastructure to meet the increasing demand for battery recycling.

Regulatory Framework and Initiatives

Global Regulations and Directives

Regulatory frameworks play a crucial role in promoting and regulating battery recycling. Governments around the world are implementing regulations and directives that require manufacturers and consumers to take responsibility for the proper disposal and recycling of batteries. These regulations ensure that batteries are not only recycled but also recycled in an environmentally friendly and safe manner.

Manufacturer Responsibility

Many countries have imposed regulations that hold manufacturers responsible for the entire lifecycle of their products, including battery recycling. Manufacturers are required to establish take-back programs and contribute to the funding of recycling initiatives. This approach encourages manufacturers to design batteries with recycling in mind and ensures that they have a vested interest in promoting sustainable practices.

Extended Producer Responsibility (EPR)

Extended Producer Responsibility (EPR) is a policy approach that makes manufacturers responsible for the entire lifecycle of their products, including their disposal and recycling. EPR programs require manufacturers to take financial and operational responsibility for the collection, recycling, and proper disposal of their batteries. This approach encourages manufacturers to design products that are easier to recycle and promotes the establishment of efficient recycling systems.

Research and Development Funding

To drive innovation in battery recycling technologies, research and development funding is crucial. Governments, research institutions, and industry associations are investing in R&D to develop new and improved recycling processes. This funding enables the exploration of emerging technologies and helps overcome barriers in battery recycling.

Emerging Technologies

Hydrometallurgical Processes

Hydrometallurgical processes involve the use of aqueous solutions to extract metals from batteries. These processes offer advantages such as lower energy consumption and reduced environmental impact compared to traditional pyrometallurgical processes. By optimizing and refining hydrometallurgical methods, we can improve the efficiency and sustainability of battery recycling.

Pyrometallurgical Processes

Pyrometallurgical processes involve the use of high temperatures to recover metals from batteries. These processes have been widely used in the recycling industry but can be energy-intensive and result in high emissions. Research and development efforts are focused on improving pyrometallurgical processes to reduce their environmental impact and increase efficiency.

Direct Cathode Recycling

Direct cathode recycling is a promising technology that aims to recover cathode materials directly from spent batteries. This approach eliminates the need for intermediate steps such as shredding and chemical processing, reducing energy consumption and improving overall efficiency. By directly recycling cathode materials, we can minimize the loss of valuable materials and simplify the recycling process.

Closed-Loop Recycling

Closed-loop recycling refers to a recycling system where materials from discarded batteries are used to produce new batteries. This approach aims to create a circular supply chain and reduce the dependency on virgin materials. By implementing closed-loop recycling, we can significantly decrease the environmental impact of battery production and reduce the need for raw material extraction.

Economic and Environmental Benefits

Resource Conservation

Battery recycling contributes to resource conservation by recovering valuable materials from spent batteries. By reusing these materials, we reduce the demand for virgin resources, such as lithium and cobalt, which are often sourced from environmentally sensitive areas. Recycling also helps to conserve other materials like nickel, aluminum, and graphite, reducing the overall environmental impact of battery production.

Reduced Carbon Emissions

The recycling of electric vehicle batteries leads to a reduction in carbon emissions throughout the battery lifecycle. By reusing materials from recycled batteries, the need for mining, refining, and manufacturing of new materials is reduced, resulting in lower emissions associated with these processes. Additionally, the use of second-life battery cells in energy storage systems helps to integrate more renewable energy into the grid, further reducing carbon emissions.

Job Creation

Battery recycling not only benefits the environment but also creates job opportunities. As the demand for battery recycling increases, there is a need for skilled workers in various stages of the recycling process, including collection, sorting, chemical processing, and metallurgical processing. The development of a robust recycling industry can contribute to economic growth and provide employment opportunities in the green sector.

Circular Economy

Battery recycling is an essential component of the circular economy, where resources are kept in use for as long as possible. By closing the loop on battery materials, we reduce waste and minimize the environmental impact of battery production and disposal. The circular economy approach aims to create a sustainable and regenerative system where resources are continuously reused and waste is minimized.

Collaboration and Industry Efforts

Public-Private Partnerships

Public-private partnerships play a crucial role in advancing battery recycling efforts. Collaboration between governments, recycling facilities, and manufacturers can help create a more efficient and sustainable recycling infrastructure. By pooling resources, sharing expertise, and leveraging each other’s strengths, public-private partnerships can drive innovation and overcome the challenges in battery recycling.

Collaborative Research Projects

Collaborative research projects bring together scientists, engineers, and industry experts to develop new recycling technologies and improve existing processes. By sharing knowledge and resources, these projects accelerate the development of innovative solutions and drive progress in battery recycling. Collaborative research projects also foster cross-sector collaboration and ensure that research efforts align with the needs of the industry.

Industry Associations and Alliances

Industry associations and alliances play a significant role in promoting best practices and driving sustainability efforts in battery recycling. These organizations bring together manufacturers, recyclers, and other stakeholders to develop common standards, share information, and advocate for the advancement of recycling technologies. Industry associations and alliances also provide a platform for collaboration and facilitate knowledge sharing among stakeholders.

Knowledge Sharing Platforms

Knowledge sharing platforms, such as conferences, workshops, and online forums, play an important role in facilitating dialogue and sharing best practices in battery recycling. These platforms bring together experts from various fields and provide opportunities for networking and collaboration. By fostering knowledge exchange, these platforms contribute to the continuous improvement of battery recycling processes.

Consumer Awareness and Education

Importance of Battery Recycling

Creating awareness about the importance of battery recycling is crucial to encourage consumer participation. Many consumers may not be aware of the environmental and economic benefits of recycling their used batteries. By educating consumers about the impact of battery disposal on the environment and the potential for resource recovery, we can motivate them to actively participate in battery recycling programs.

Promoting Sustainable EV Ownership

Promoting sustainable electric vehicle (EV) ownership goes hand in hand with battery recycling efforts. Educating consumers about the lifecycle of EV batteries and the importance of responsible battery disposal can help create a more sustainable EV ecosystem. By highlighting the role of battery recycling in reducing the environmental impact of EVs, we can encourage consumers to make environmentally conscious choices.

Proper Disposal Guidelines

Providing clear and accessible guidelines for the proper disposal of batteries is essential. Consumers need to know where and how to dispose of their used batteries to ensure they are collected and recycled responsibly. Collaboration between manufacturers, retailers, and recycling centers can help establish collection points and provide consumers with the necessary information.

Educational Campaigns

Educational campaigns play a vital role in raising awareness and promoting behavior change. By utilizing various channels such as media, social platforms, and community outreach, educational campaigns can inform the public about battery recycling initiatives and the importance of their participation. These campaigns can also provide practical tips for battery disposal and highlight success stories in battery recycling.

Future Perspectives

Advancements in Battery Technology

Advancements in battery technology will have a significant impact on the recycling process. As new types of batteries, such as solid-state batteries, become more prevalent, recycling facilities will need to adapt and develop specialized processes. By staying ahead of technological developments, we can ensure that the recycling infrastructure is prepared to handle future battery systems effectively.

Improved Recycling Technologies

Continued research and development efforts will lead to improved recycling technologies. This includes advancements in chemical processing, metallurgical processing, and the development of new methods for extracting and purifying valuable materials. These improvements will increase the efficiency and sustainability of the recycling process, making it more economically viable and environmentally friendly.

Standardized Processes and Regulations

Standardized processes and regulations will be crucial for the future of battery recycling. As the industry grows, it is essential to establish clear guidelines and standards that ensure a consistent and high-quality recycling process. Standardization will also facilitate knowledge sharing and collaboration among different players in the recycling ecosystem.

Circular Supply Chains

The concept of circular supply chains, where materials are continuously recycled and reused, will play a significant role in the future of battery recycling. By establishing closed-loop systems and promoting the use of recycled materials in battery production, we can reduce dependency on virgin resources and minimize waste. Implementing circular supply chains will require collaboration across the entire value chain, from manufacturers to consumers.

In conclusion, the recycling and reuse of electric vehicle batteries present significant opportunities for resource conservation, reduced carbon emissions, and job creation. Through a comprehensive recycling process that includes collection, sorting, shredding, chemical processing, and metallurgical processing, valuable materials such as lithium and cobalt can be recovered and reused. The recovery and reuse of battery cells further extend their lifespan and contribute to applications such as battery energy storage systems, off-grid energy storage, and grid stabilization. However, the recycling process also faces challenges such as battery design complexity, limited recycling facilities, and safety concerns. To address these challenges, a regulatory framework, collaboration, and industry efforts are essential. Furthermore, emerging technologies such as hydrometallurgical and pyrometallurgical processes, direct cathode recycling, and closed-loop recycling show promise in improving the efficiency and sustainability of battery recycling. By promoting consumer awareness and education, encouraging sustainable EV ownership, and implementing proper disposal guidelines, we can enhance participation in battery recycling programs. Looking ahead, advancements in battery technology, improved recycling technologies, standardized processes, and circular supply chains will shape the future of battery recycling, ensuring a more sustainable and resource-efficient industry.