Welcome to the fascinating world of electric vehicles and their impact on the sustainable use of rare earth metals. As we explore the increasing popularity of electric cars and the environmental benefits they offer, we will delve into the importance of sustainable sourcing and recycling of rare earth metals used in their production. Join us on this informative journey to deepen your understanding of the intersection between green technology and responsible resource management. How Do Electric Vehicles Impact The Sustainable Use Of Rare Earth Metals?

Introduction

Electric vehicles (EVs) are becoming increasingly popular as a more sustainable alternative to traditional gasoline-powered vehicles. With this shift towards cleaner transportation options, there is a growing concern about the environmental impact of EVs, particularly in regards to the use of rare earth metals. So, how do electric vehicles impact the sustainable use of rare earth metals? Let’s delve into the details and explore this important topic further.

Overview of Rare Earth Metals

Rare earth metals are a group of seventeen elements that are essential in the manufacturing of various technologies, including electric vehicles. These metals are not actually rare in nature, but they are dispersed and difficult to extract in high concentrations. Some of the most commonly used rare earth metals in EVs include neodymium, dysprosium, and praseodymium. These metals are used in the production of magnets, batteries, and electric motors in electric vehicles.

The Environmental Impact of Rare Earth Metal Mining

The mining and extraction of rare earth metals can have significant environmental consequences. The process of extracting these metals can result in deforestation, soil erosion, water pollution, and habitat destruction. Additionally, the use of toxic chemicals and heavy metals in the extraction process can have long-lasting effects on local ecosystems. This raises concerns about the sustainability of rare earth metal mining and its impact on the environment.

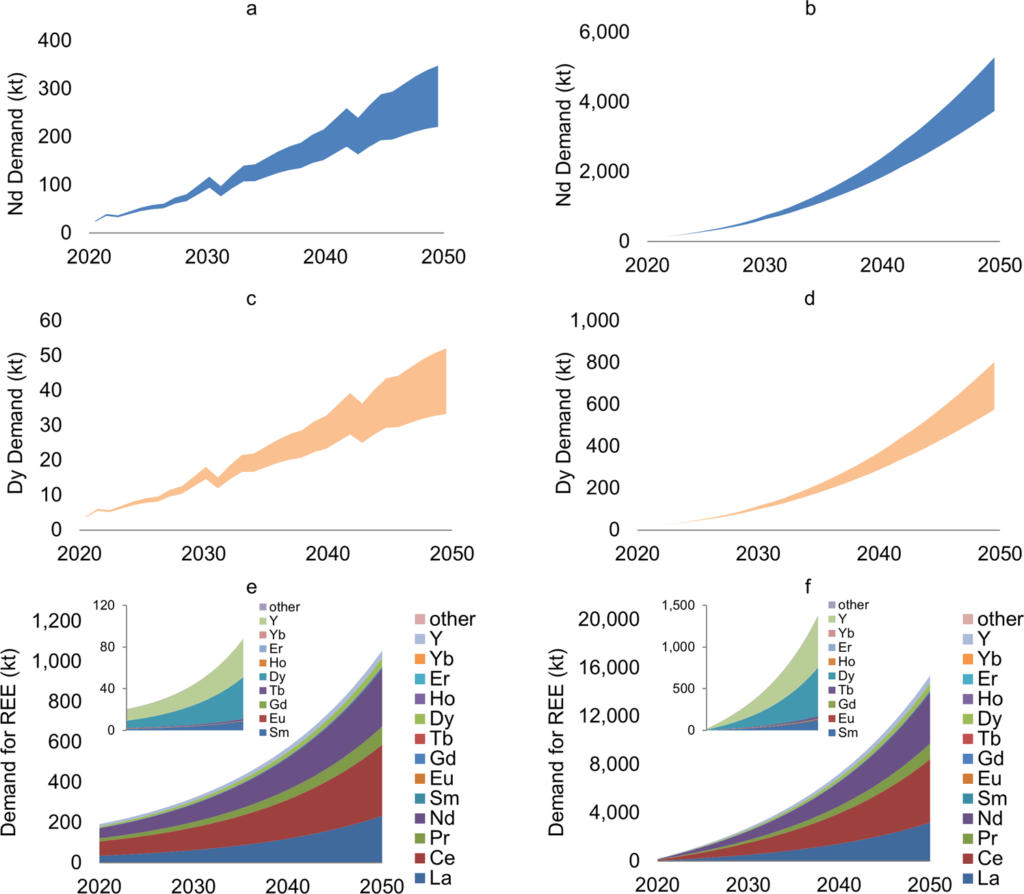

Impact of Electric Vehicles on Rare Earth Metal Demand

The growing demand for electric vehicles has led to an increase in the production of rare earth metals. As EVs become more prevalent, the need for materials like neodymium, dysprosium, and praseodymium has also risen. This surge in demand has raised questions about the long-term availability of these critical resources and the sustainability of their use in electric vehicles.

Neodymium in Electric Vehicle Motors

Neodymium is a key component in the production of permanent magnets used in electric vehicle motors. These magnets are essential for creating the magnetic fields that drive the motor and propel the vehicle forward. As the demand for EVs continues to grow, so does the need for neodymium. This has led to concerns about potential shortages of this critical rare earth metal in the future.

Dysprosium and Praseodymium in EV Batteries

Dysprosium and praseodymium are also crucial elements in the manufacturing of lithium-ion batteries used in electric vehicles. These metals help enhance the performance and efficiency of the batteries, allowing for longer driving ranges and faster charging times. However, the limited supply of dysprosium and praseodymium raises questions about the sustainability of using these rare earth metals in EV batteries.

Strategies for Sustainable Rare Earth Metal Use in Electric Vehicles

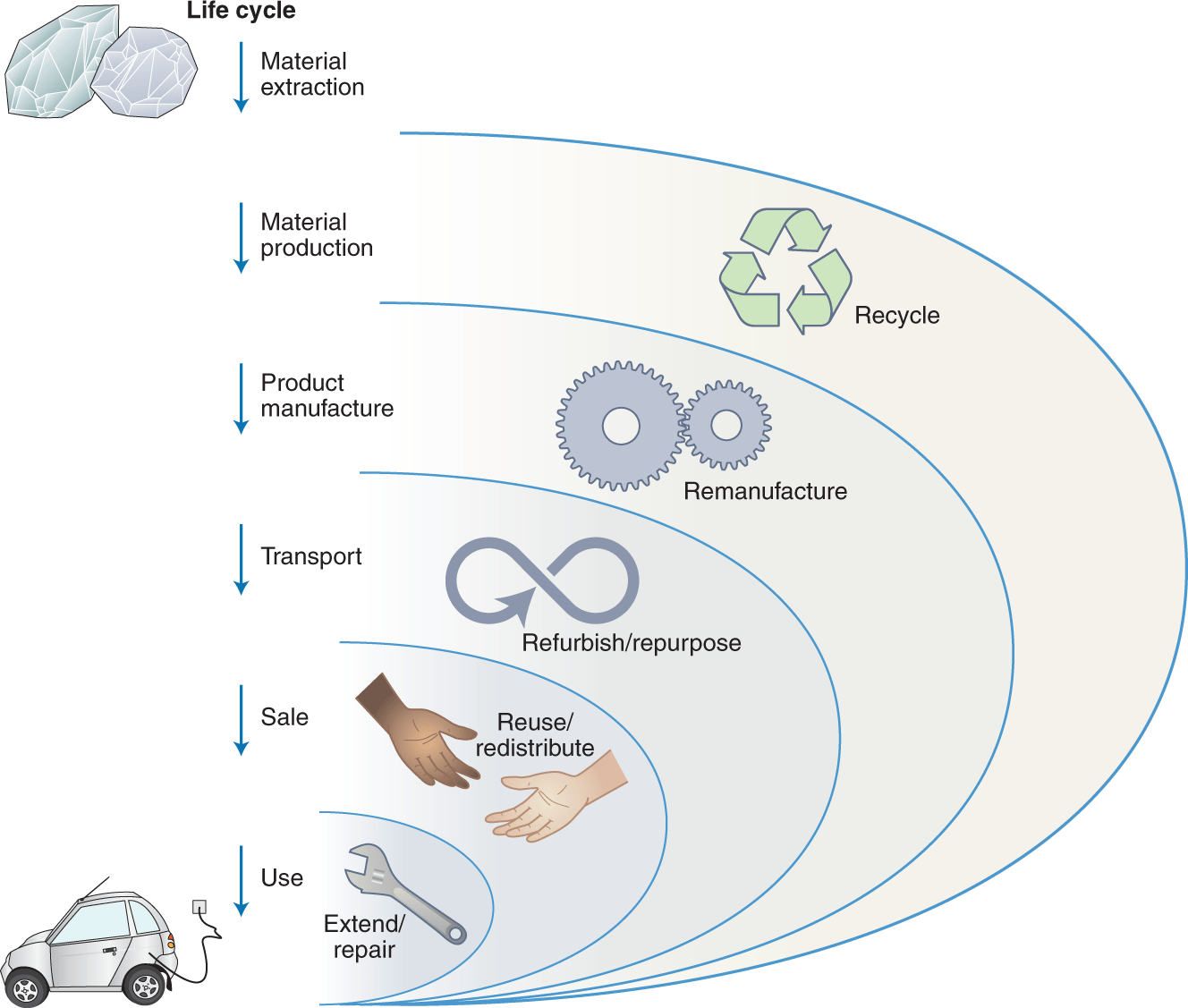

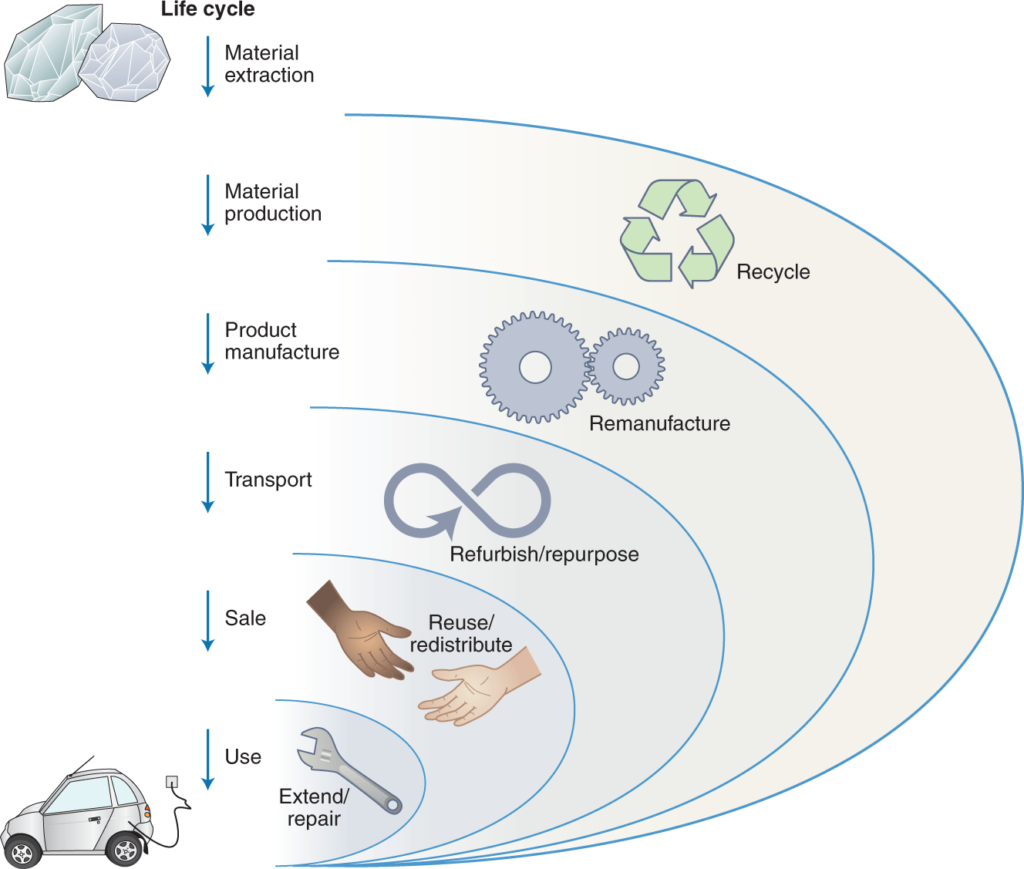

To address the environmental and sustainability concerns associated with rare earth metal use in electric vehicles, various strategies have been proposed. These strategies aim to reduce the demand for these critical resources, promote recycling and reuse, and diversify the supply chain of rare earth metals.

Diversification of Rare Earth Metal Supply

One approach to promoting the sustainable use of rare earth metals in electric vehicles is to diversify the supply chain. By sourcing these critical resources from multiple locations and reducing dependence on a single country or region, the risk of supply chain disruptions can be minimized. This strategy involves exploring new sources of rare earth metals outside of traditional mining hotspots like China.

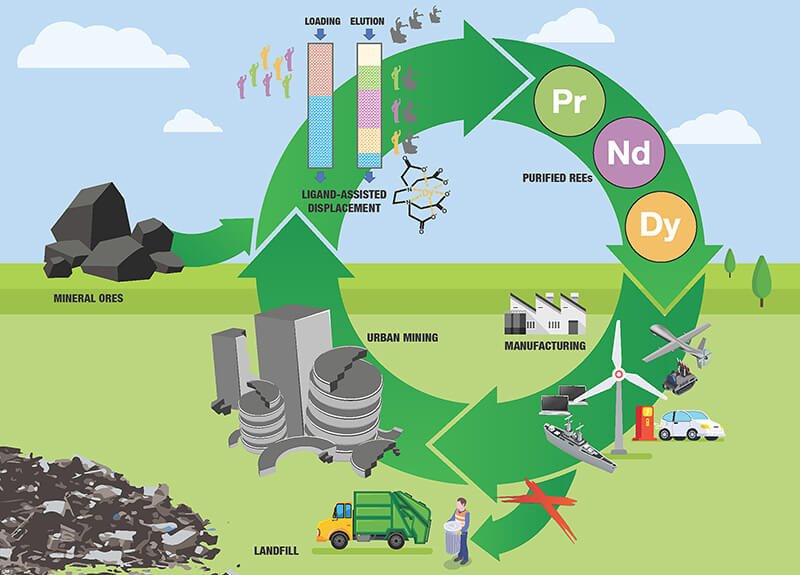

Recycling and Reuse of Rare Earth Metals

Another key strategy for sustainable rare earth metal use in electric vehicles is recycling and reuse. By recovering rare earth metals from old EV batteries and other electronic devices, the need for new mining and extraction can be reduced. Recycling these valuable materials not only conserves natural resources but also helps reduce the environmental impact of rare earth metal production.

Development of Alternative Materials

Innovations in material science and engineering have led to the development of alternative materials that can substitute for rare earth metals in electric vehicle components. Researchers are exploring the use of magnet materials that do not rely on rare earth elements, as well as new battery chemistries that are less dependent on dysprosium and praseodymium. These alternative materials offer a promising solution to the sustainability challenges associated with rare earth metal use in EVs.

Conclusion

As electric vehicles continue to gain traction as a more sustainable mode of transportation, the impact of rare earth metal use on the environment remains a critical issue. The growing demand for materials like neodymium, dysprosium, and praseodymium in EVs raises concerns about the sustainability of their extraction and production. By implementing strategies such as diversifying the supply chain, promoting recycling and reuse, and developing alternative materials, we can work towards a more sustainable future for electric vehicles and rare earth metals alike. Remember, the choices we make today will shape the future of transportation and the planet for generations to come.