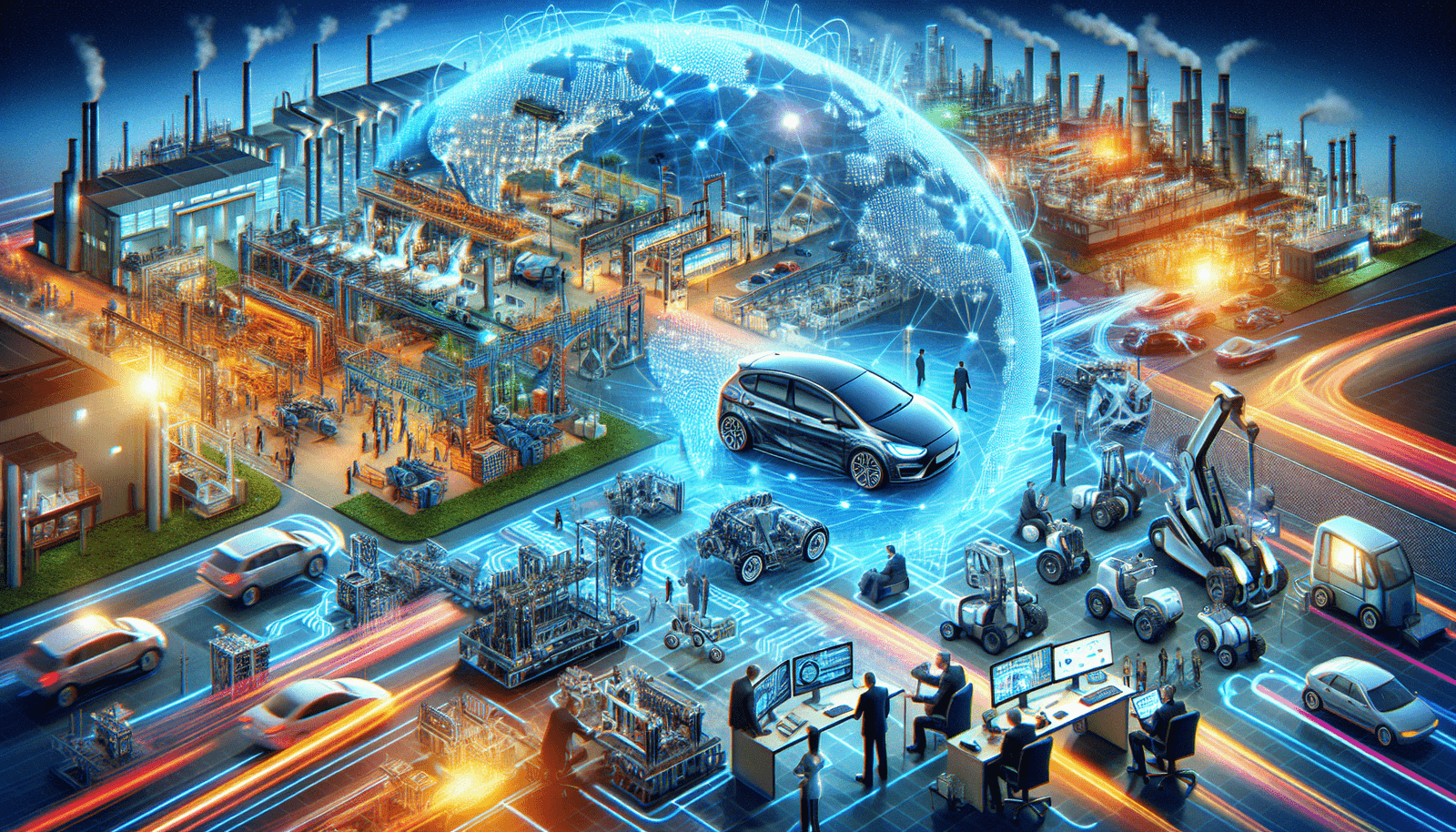

Have you ever wondered how the electric vehicle supply chain is changing worldwide? From the production of electric vehicle components to the building of charging infrastructure, the global network supporting the growth of electric vehicles is undergoing a remarkable transformation. In this article, we will explore the latest developments and trends in the electric vehicle supply chain, highlighting key players and advancements that are shaping the future of transportation. Get ready to be fascinated by the evolving landscape of electric vehicles around the world!

Growing Demand for Electric Vehicles

The demand for electric vehicles (EVs) has been rapidly growing across the globe. With increasing environmental concerns and the need to reduce carbon emissions, more and more consumers are turning towards electric vehicles as a sustainable transportation option. This shift in consumer preferences has been a major driving force behind the rising sales of electric vehicles.

Rising Sales of Electric Vehicles

In recent years, the sales of electric vehicles have seen a significant increase. This can be attributed to several factors, including advancements in technology, government initiatives, and increased consumer awareness. As EVs become more affordable and offer longer driving ranges, consumers are becoming more inclined towards embracing this new form of transportation.

Government Initiatives to Promote Electric Vehicles

Governments around the world have recognized the potential of electric vehicles in reducing greenhouse gas emissions and improving air quality. As a result, various initiatives and policies have been implemented to promote the adoption of electric vehicles. These include financial incentives, tax credits, and rebates for EV purchases, as well as investment in charging infrastructure development.

Increasing Consumer Awareness and Adoption

Consumer awareness and acceptance of electric vehicles have been steadily increasing. With greater access to information and education about the benefits of EVs, consumers are now more informed about the advantages of electric vehicles, such as lower operating costs, reduced emissions, and a quieter driving experience. This has led to a greater willingness to adopt electric vehicles as a viable alternative to traditional gasoline-powered vehicles.

Battery Technology Advancements

One of the key factors driving the growth of electric vehicles is the continual advancement in battery technology. The development of more efficient and high-performing batteries has significantly contributed to the increased range and improved performance of electric vehicles.

Improvements in Lithium-ion Batteries

Lithium-ion batteries have been the dominant battery technology in the electric vehicle industry. Over the years, there have been considerable improvements in their energy density, allowing for longer driving ranges and improved overall performance. These advancements have also led to the reduction in battery costs, making electric vehicles more affordable for consumers.

Emergence of Solid-state Batteries

Solid-state batteries are poised to revolutionize the electric vehicle industry. These batteries offer higher energy density, faster charging times, and improved safety compared to traditional lithium-ion batteries. With ongoing research and development efforts, solid-state batteries are expected to be commercially available in the near future, further enhancing the capabilities of electric vehicles.

Development of Advanced Battery Management Systems

The optimization and management of battery performance are crucial for maximizing the efficiency and lifespan of electric vehicle batteries. Advanced battery management systems (BMS) are being developed to monitor and control various aspects of battery operation, such as temperature, voltage, and current. These systems ensure the safety and reliability of electric vehicle batteries while optimizing their performance.

Expansion of Charging Infrastructure

The availability of a robust charging infrastructure is necessary to support the widespread adoption of electric vehicles. Efforts are being made to expand the charging infrastructure network to ensure convenient and accessible charging options for EV owners.

Installation of Public Charging Stations

Public charging stations are being installed in various locations, such as parking lots, shopping centers, and highways, to provide EV owners with reliable and convenient charging options. These charging stations enable drivers to charge their vehicles while going about their daily activities, alleviating range anxiety and promoting the adoption of electric vehicles.

Integration of Charging Infrastructure with Smart Grids

Smart grid technologies are being leveraged to integrate charging infrastructure with the power grid. This allows for efficient management and optimization of electricity distribution, ensuring that charging stations are supplied with adequate power during peak demand periods. The integration of charging infrastructure with smart grids also enables demand response capabilities, enabling utilities to balance electricity supply and demand effectively.

Advancements in Wireless Charging Technology

Wireless charging technology is an emerging solution that eliminates the need for physical connections between the charger and the vehicle. This technology enables EV owners to simply park their vehicles over specially designed charging pads, which then wirelessly transfer power to the vehicle’s battery. The development of efficient and scalable wireless charging solutions has the potential to revolutionize the charging experience for electric vehicle owners.

Increased Collaboration across the Supply Chain

Collaboration across the electric vehicle supply chain has become crucial for the efficient and sustainable growth of the industry. Partnerships and collaborations between automakers, battery manufacturers, and charging infrastructure providers are driving innovation and accelerating the adoption of electric vehicles.

Partnerships between Automakers and Battery Manufacturers

Automakers are forging strategic partnerships with battery manufacturers to secure a stable supply of high-quality batteries for their electric vehicles. These partnerships involve joint research and development initiatives to improve battery performance and reduce costs. By working together, automakers and battery manufacturers can drive innovation and enhance the overall competitiveness of electric vehicles.

Collaborations between Automakers and Charging Infrastructure Providers

To address the growing demand for charging infrastructure, automakers are collaborating with charging infrastructure providers to establish a wide network of charging stations. This collaboration ensures that electric vehicle owners have access to a reliable and extensive charging infrastructure, further boosting the confidence and adoption of electric vehicles.

Integration of Startups in the Electric Vehicle Ecosystem

Startups have been playing a significant role in driving innovation and disruption in the electric vehicle industry. These startups bring fresh ideas, technologies, and business models to the table, challenging traditional players and accelerating the pace of change. By integrating startups into the electric vehicle ecosystem, established companies can tap into their entrepreneurial spirit and leverage their expertise to fuel industry growth.

Localization of Supply Chain Activities

To reduce costs and promote sustainability, there is a growing focus on localizing supply chain activities within the electric vehicle industry. This includes domestic manufacturing of EV components, establishment of battery gigafactories, and sourcing raw materials locally.

Domestic Manufacturing of Electric Vehicle Components

To support the growth of the electric vehicle industry, countries are investing in domestic manufacturing capabilities for EV components. This reduces reliance on imports and fosters the development of a competitive and sustainable supply chain. By manufacturing components locally, automakers can also take advantage of closer proximity to suppliers and reduce transportation costs.

Establishment of Battery Gigafactories

Battery gigafactories are large-scale manufacturing facilities dedicated to producing electric vehicle batteries. These facilities enable economies of scale, allowing for increased production capacity and lower battery costs. The establishment of battery gigafactories has become a critical component in securing a stable and cost-effective supply of batteries for electric vehicles.

Local Sourcing of Raw Materials

The localization of the supply chain also involves sourcing raw materials locally. This reduces dependence on foreign suppliers and ensures a secure and sustainable supply of raw materials, such as lithium, cobalt, and nickel, which are essential for battery production. By sourcing raw materials locally, the electric vehicle industry can minimize environmental impacts and support local economies.

Transition to Sustainable Materials

As the electric vehicle industry grows, there is an increasing focus on the use of sustainable materials in the manufacturing of EVs and batteries. This transition involves reducing the dependence on rare earth metals, exploring alternative battery materials, and implementing circular economy principles.

Reduction of Dependence on Rare Earth Metals

Rare earth metals, such as neodymium and dysprosium, are crucial for the production of electric vehicle motors and magnets. However, these metals are scarce and often associated with environmental and social issues in their extraction and processing. To reduce reliance on rare earth metals, researchers and manufacturers are exploring alternative materials and developing more efficient motor designs.

Exploration of Alternative Battery Materials

In addition to reducing the dependence on rare earth metals, the electric vehicle industry is actively exploring alternative battery materials. This includes the use of materials like graphene, sodium-ion, and magnesium-ion as potential alternatives to lithium-ion batteries. By diversifying the range of battery materials, the industry can improve battery performance, reduce costs, and enhance sustainability.

Implementation of Circular Economy Principles

The implementation of circular economy principles is gaining traction in the electric vehicle industry. This involves designing products and systems to minimize waste and maximize the reuse and recycling of materials. Battery recycling programs are being established to recover valuable materials from used batteries, reducing the environmental impact of battery production and disposal. By adopting circular economy principles, the electric vehicle industry can foster a more sustainable and resource-efficient supply chain.

Role of Artificial Intelligence and Data Analytics

Artificial intelligence (AI) and data analytics are revolutionizing the electric vehicle industry, enabling improved vehicle production, supply chain management, and overall efficiency.

Utilization of AI in Vehicle Production and Supply Chain Management

AI is being employed in vehicle production to optimize processes, enhance quality control, and improve efficiency. AI-powered robots and autonomous systems are used to perform complex tasks, increasing production speed and reducing errors. AI is also utilized in supply chain management to optimize inventory management, demand forecasting, and logistics, ensuring that the right parts and components are available when and where they are needed.

Data-driven Predictive Maintenance of Electric Vehicle Components

With the extensive use of sensors and connectivity in electric vehicles, vast amounts of data are generated. Data analytics are utilized to monitor and analyze the performance of various components, such as batteries and motors. This enables predictive maintenance, where potential issues and failures can be identified in advance, allowing for proactive maintenance and minimizing downtime. By leveraging data-driven insights, electric vehicle operators can optimize maintenance schedules and ensure the reliability and longevity of their vehicles.

Enhanced Supply Chain Efficiency through Analytics

Data analytics is also used to enhance supply chain efficiency. By analyzing data related to production, inventory, and distribution, companies can identify bottlenecks, optimize workflows, and reduce costs. Machine learning algorithms are employed to identify patterns and trends, enabling demand forecasting and inventory management optimization. This ensures that supply chain operations are streamlined, minimizing waste and enhancing overall efficiency.

Shift towards Vertical Integration

The electric vehicle industry is witnessing a shift towards vertical integration, with companies expanding their involvement across different stages of the supply chain.

Automakers Investing in Battery Manufacturing

To secure a stable supply of batteries and gain control over key EV components, automakers are increasingly investing in battery manufacturing facilities. By vertically integrating battery production, automakers can develop batteries that are specifically tailored to their vehicles, optimize costs, and reduce dependence on external suppliers. This trend is seen as a strategic move to improve competitiveness and ensure the availability of advanced battery technologies for future electric vehicle models.

Charging Infrastructure Providers Entering Vehicle Production

Charging infrastructure providers are diversifying their activities by entering the electric vehicle production market. By utilizing their expertise in charging technology and infrastructure deployment, these companies aim to offer integrated solutions that encompass both the vehicle and the charging infrastructure. This vertical integration allows for closer alignment between charging networks and vehicles, ensuring seamless compatibility and enhancing the overall charging experience.

Battery Manufacturers Expanding into Electric Vehicle Production

Battery manufacturers are also expanding their operations by venturing into electric vehicle production. By leveraging their expertise in battery technology, these companies aim to develop their own electric vehicle models and capture a share of the growing EV market. This vertical integration enables them to showcase their battery technologies in their own vehicles while diversifying their revenue streams beyond battery manufacturing.

Government Policies and Regulations

Government policies and regulations play a crucial role in shaping the electric vehicle industry. Various measures are being implemented to support the growth of electric vehicles, promote sustainable battery production, and reduce emissions.

Financial Incentives for Electric Vehicle Manufacturing

Governments provide financial incentives, such as grants, subsidies, and tax credits, to encourage automakers to manufacture electric vehicles. These incentives help reduce the upfront costs of electric vehicle production and promote the adoption of sustainable transportation options. By providing financial support, governments aim to accelerate the transition towards electric vehicles and reduce reliance on fossil fuels.

Mandates for Zero-Emission Vehicles

Many governments have implemented mandates and targets for zero-emission vehicles. These mandates require automakers to produce a certain percentage of electric vehicles or vehicles with zero tailpipe emissions. By setting these targets, governments create a market demand for electric vehicles and incentivize automakers to invest in electric vehicle research, development, and production. These mandates are viewed as crucial for reducing greenhouse gas emissions and achieving sustainability goals.

Regulations for Sustainable Battery Production and Disposal

To ensure the sustainable production and disposal of electric vehicle batteries, governments have implemented regulations and guidelines. These regulations govern the responsible sourcing of raw materials, the reduction of hazardous substances in battery production, and the establishment of recycling and disposal programs. By enforcing these regulations, governments aim to minimize the environmental impact of battery production and disposal and promote the development of a sustainable battery supply chain.

Investments in Research and Development

Investments in research and development (R&D) are vital for the continuous advancement of electric vehicles and the electric vehicle supply chain. Governments, industry players, and research institutions are actively funding R&D initiatives to drive innovation and develop new technologies.

Research on Advanced Battery Technologies

Significant research efforts are focused on advancing battery technologies for electric vehicles. This includes research into new materials, battery chemistries, and energy storage systems. By investing in battery research, stakeholders aim to improve battery performance, increase energy density, and extend battery life, ultimately enhancing the range and overall capabilities of electric vehicles.

Development of Fast-charging Solutions

Research and development are also being conducted to develop fast-charging solutions for electric vehicles. This involves improving the charging efficiency, reducing charging times, and addressing the challenges associated with high-power charging. The development of fast-charging solutions is essential for providing convenient and accessible charging options for electric vehicle owners, further promoting the adoption of electric vehicles.

Innovations in Supply Chain Optimization

Research and development efforts are focused on optimizing supply chain operations within the electric vehicle industry. This includes the development of advanced supply chain management systems, logistics optimization algorithms, and inventory management solutions. By leveraging technology and data analytics, researchers aim to enhance supply chain efficiency, reduce costs, and improve overall performance.

In conclusion, the electric vehicle supply chain is evolving globally to meet the growing demand for sustainable transportation. Advancements in battery technology, expansion of charging infrastructure, increased collaboration across the supply chain, localization of supply chain activities, transition to sustainable materials, utilization of artificial intelligence and data analytics, vertical integration, government policies and regulations, and investments in research and development are all driving the evolution of the electric vehicle supply chain. As these trends continue to shape the industry, the electric vehicle market is poised for further growth and innovation, offering a cleaner and greener transportation future.