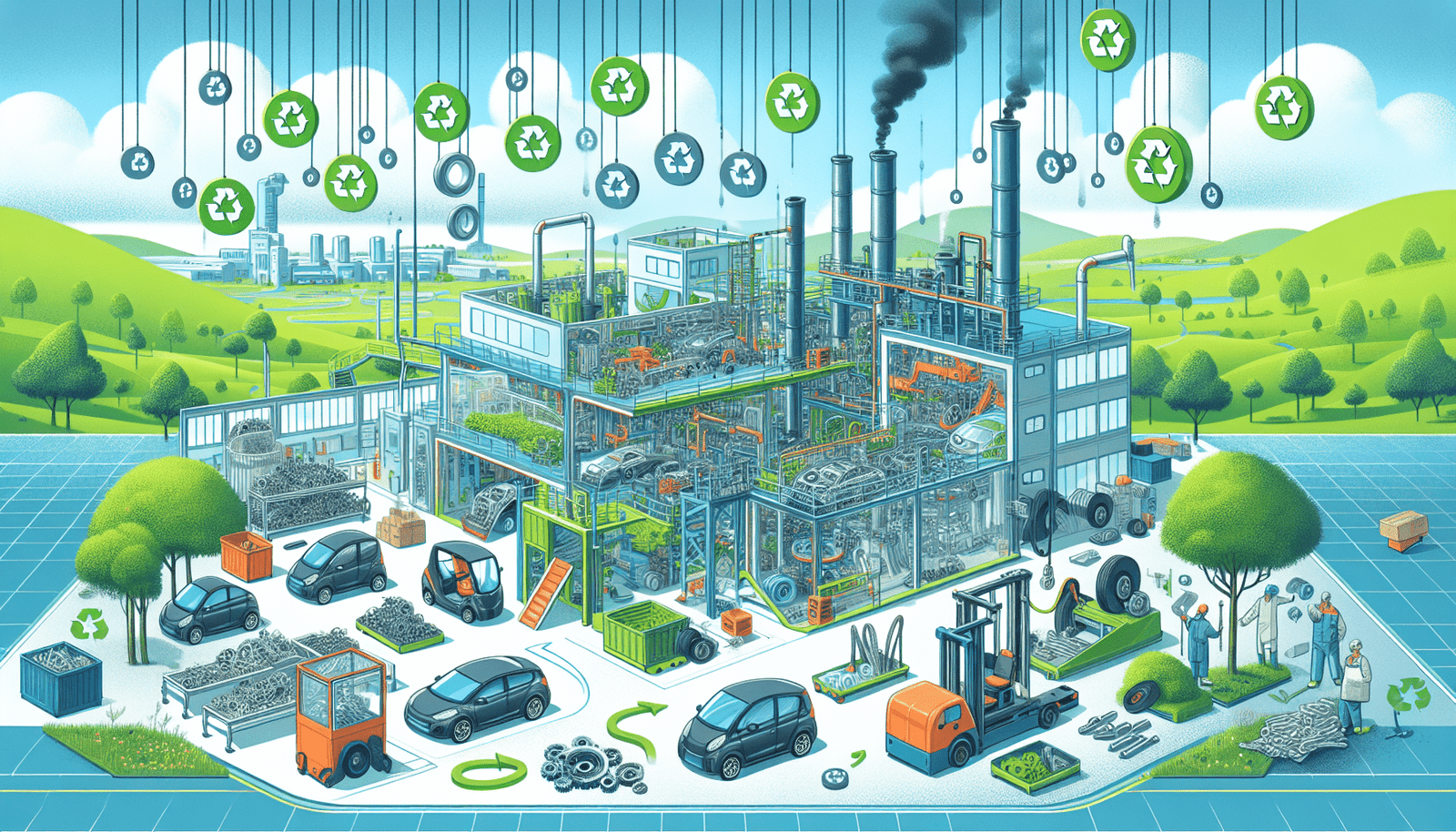

In this article, you will discover the remarkable environmental benefits that come with using recycled materials in the manufacturing of electric vehicles (EVs). As the world takes significant strides towards sustainability, recycling plays a crucial role in reducing waste and conserving resources. By utilizing recycled materials in the production of EVs, we can minimize the harmful impact on our environment, promote a circular economy, and pave the way towards a greener future. Want to learn more about how this eco-friendly approach benefits both our planet and the automotive industry? Keep reading!

This image is property of pixabay.com.

Reduced Resource Extraction and Deforestation

Conservation of non-renewable resources

Using recycled materials in electric vehicle (EV) manufacturing has significant environmental benefits, starting with the conservation of non-renewable resources. By utilizing recycled materials instead of extracting new resources, we reduce the demand for mining and drilling activities. This reduction in resource extraction helps to preserve valuable natural ecosystems and habitats that would otherwise be disrupted.

Preservation of natural habitats and ecosystems

One of the key advantages of using recycled materials in EV manufacturing is the preservation of natural habitats and ecosystems. Traditional resource extraction methods often involve deforestation, destroying the homes of numerous plant and animal species. By minimizing the need for new raw materials and relying on recycled materials, we can help protect these delicate ecosystems and promote biodiversity.

Energy and Emissions Savings

Reduced energy consumption in material production

The use of recycled materials in EV manufacturing results in significant energy savings compared to producing materials from scratch. Extracting and processing raw materials consumes a substantial amount of energy, which contributes to greenhouse gas emissions and pollution. By employing recycled materials, we greatly diminish the energy requirements associated with material production, thereby reducing our carbon footprint.

Lower greenhouse gas emissions

In line with reduced energy consumption, the use of recycled materials also leads to lower greenhouse gas emissions. The extraction and processing of raw materials release substantial amounts of carbon dioxide and other harmful gases into the atmosphere. By avoiding these processes and utilizing recycled materials, we can tangibly reduce the emissions associated with EV manufacturing, contributing to mitigating climate change.

Waste Reduction and Landfill Diversion

Decreased landfill space requirements

The adoption of recycled materials in EV manufacturing significantly decreases the need for landfill space. Without a sustainable solution, many waste products associated with manufacturing processes end up in landfills, taking up valuable space. By reusing and repurposing materials through recycling, we divert waste from landfills, minimizing our environmental impact and optimizing the use of available land resources.

Less pollution from waste disposal

When waste is improperly disposed, it can contaminate soil, water, and air, causing severe pollution. By utilizing recycled materials, we reduce the amount of waste generated by EV manufacturing and subsequently decrease the potential pollution from waste disposal. This environmentally-friendly approach helps to safeguard natural resources, protect ecosystems, and promote the well-being of both human and animal populations.

Improved Air Quality

Reduced emissions from manufacturing processes

By incorporating recycled materials into EV manufacturing, we can substantially reduce emissions from production processes. Manufacturing activities, such as melting, refining, and shaping raw materials, are often significant contributors to air pollution. By substituting these processes with the use of recycled materials, we minimize air pollutant emissions, leading to improved air quality and a healthier environment for all.

Minimized air pollutants during waste disposal

In addition to reducing emissions during manufacturing, the use of recycled materials helps curtail the release of air pollutants during waste disposal as well. When waste is not properly managed, harmful pollutants can be released into the air during decomposition or incineration. By focusing on recycling and reusing materials, we eliminate the need for such disposal methods and subsequently minimize the release of air pollutants, improving the overall air quality in our communities.

This image is property of pixabay.com.

Water Conservation and Pollution Reduction

Decreased water usage in material production

The incorporation of recycled materials in EV manufacturing also contributes to water conservation. The extraction and processing of raw materials often require significant amounts of water, leading to the depletion of freshwater resources. By utilizing recycled materials instead, we can greatly reduce the water usage associated with material production, helping to conserve this essential resource for future generations.

Less water pollution from waste disposal

Improper disposal of waste materials can contaminate water sources, posing a significant threat to aquatic ecosystems and human health. By recycling materials in EV manufacturing, we minimize the amount of waste that ends up in water bodies, reducing the risk of water pollution. Through this approach, we work towards safeguarding our water resources and preserving the well-being of both marine life and communities that rely on clean water.

Lower Carbon Footprint

Reduced carbon emissions during material extraction and production

Using recycled materials in EV manufacturing helps to decrease the carbon emissions associated with the extraction and production of raw materials. These processes often involve the burning of fossil fuels, releasing substantial amounts of carbon dioxide into the atmosphere. By relying on recycled materials instead, we can significantly lower our carbon footprint, contributing to the global efforts of combating climate change and promoting a sustainable future.

Decreased carbon emissions during waste management

The use of recycled materials also helps lower carbon emissions during waste management. Improper waste disposal methods, such as landfilling or incineration, can result in the release of greenhouse gases. By transitioning to a circular economy approach with recycling at its core, we reduce the amount of waste that needs disposal while simultaneously decreasing emissions, further reducing our carbon footprint and mitigating the impacts of climate change.

This image is property of pixabay.com.

Extended Lifespan of Materials

Reuse and reprocessing of materials

One of the key environmental benefits of using recycled materials in EV manufacturing is the extended lifespan of the materials themselves. Recycled materials, such as metals and plastics, can be repeatedly reprocessed and reused, reducing the need for new production. By embracing this circular approach, we maximize the utility of materials, minimize waste generation, and promote a more sustainable and resource-efficient manufacturing industry.

Increased durability and longevity of products

Incorporating recycled materials into EV manufacturing can also lead to increased durability and longevity of the final products. The use of high-quality recycled materials ensures that EVs are built to last, reducing the frequency of replacements and extending their lifespan. By designing and manufacturing products that can withstand the test of time, we reduce resource consumption and waste generation, thereby promoting a more sustainable and responsible approach to product development.

Promotion of Circular Economy

Closing the loop of resource consumption

The utilization of recycled materials in EV manufacturing plays a crucial role in promoting a circular economy. In a traditional linear economy, resources are extracted, processed, used, and then discarded as waste. However, by embracing recycling, we close the loop of resource consumption, ensuring that materials are continuously reused and repurposed instead of being discarded. This transition towards a circular economy helps reduce the demand for raw materials, minimize waste generation, and create a more sustainable and resilient ecosystem.

Reduction of waste generation

By employing recycled materials, we actively contribute to the reduction of waste generation. Rather than relying solely on new production, recycling allows us to transform waste materials into valuable resources, minimizing the amount of waste that ends up in landfills or incinerators. This reduction in waste generation significantly benefits the environment by conserving resources, reducing pollution, and fostering a more sustainable and efficient approach to manufacturing.

Economic Benefits

Creation of jobs in recycling sectors

The utilization of recycled materials in EV manufacturing also brings significant economic benefits, including the creation of jobs in recycling sectors. Recycling processes require skilled workers for collection, sorting, and processing, contributing to the growth of the recycling industry. By prioritizing the use of recycled materials, we not only help protect the environment but also stimulate economic development by generating employment opportunities and supporting local communities.

Cost savings from reduced material extraction and disposal

Incorporating recycled materials in EV manufacturing can lead to substantial cost savings. The extraction and processing of raw materials can be expensive, involving high energy and labor costs. By utilizing recycled materials, we eliminate the need for these resource-intensive processes, resulting in significant cost reductions. As a result, the use of recycled materials not only benefits the environment but also offers economic advantages, allowing for more affordable and sustainable manufacturing practices.

Enhanced Brand Image

Demonstration of commitment to sustainability

By actively incorporating recycled materials into EV manufacturing, companies can demonstrate their commitment to sustainability and environmental stewardship. This commitment helps enhance their brand image, showcasing their dedication to minimizing environmental impacts and promoting a more sustainable future. Consumers, increasingly conscious of environmental issues, are more likely to support and choose brands that prioritize sustainability, leading to increased brand loyalty and a positive public perception.

Boosting consumer perception and loyalty

Public concern for the environment is at an all-time high, with consumers actively seeking out eco-conscious products and brands. By utilizing recycled materials in EV manufacturing, companies can tap into this growing market demand and boost consumer perception and loyalty. When customers recognize a brand’s genuine commitment to sustainability and the use of recycled materials, they are more likely to choose these products, leading to increased sales and a strengthened market position.

By embracing reduced resource extraction, energy and emissions savings, waste reduction, improved air quality, water conservation, a lower carbon footprint, extended lifespan of materials, promotion of circular economy, economic benefits, and an enhanced brand image, the use of recycled materials in EV manufacturing yields numerous environmental advantages. These benefits not only help protect our natural ecosystems and resources but also contribute to the goal of building a sustainable and resilient future for generations to come.