Get ready to rev up your knowledge on the latest advancements in electric vehicle technology! In this article, we’ll take a look at the cutting-edge developments in electric vehicle motors and drivetrains. From enhanced efficiency to increased power, these breakthroughs are paving the way for a more sustainable and exhilarating driving experience. So buckle up and join us on this electrifying journey to discover the future of electric vehicles!

Battery Technology

Advancements in Lithium-ion Batteries

Lithium-ion batteries have seen significant advancements in recent years, making them the preferred choice for electric vehicles. These batteries offer improved energy density, allowing for longer driving ranges on a single charge. With ongoing research and developments, manufacturers are working on enhancing the lifespan and safety of lithium-ion batteries, thereby increasing their appeal to consumers.

Solid-State Batteries

Solid-state batteries are a promising technology that could revolutionize the electric vehicle industry. Unlike traditional lithium-ion batteries, solid-state batteries do not use a liquid electrolyte. Instead, they utilize a solid material, which enhances safety and allows for higher energy storage capacity. By eliminating the risk of flammability associated with liquid electrolytes, solid-state batteries offer a significant improvement in terms of overall safety.

Battery Management Systems

Battery management systems play a crucial role in optimizing the performance and lifespan of electric vehicle batteries. These systems monitor various parameters such as temperature, voltage, and state of charge to ensure the batteries are operating within safe limits. Additionally, advanced algorithms can predict and prevent potential issues, leading to improved battery efficiency and longevity.

Wireless Charging

Wireless charging technology has gained considerable attention in recent years. It allows for effortless charging of electric vehicles without the need for physical connections. Through electromagnetic induction, energy is wirelessly transferred from the charging pad to the vehicle’s battery. This technology offers convenience and eliminates the hassle of traditional charging methods, making it an attractive solution for electric vehicle owners.

Motor Efficiency

High-Torque Density Motors

High-torque density motors are a key development in the electric vehicle industry. These motors generate a higher amount of torque per unit of mass or size, enabling improved acceleration and overall performance. By maximizing torque output while minimizing weight and size, high-torque density motors contribute to the efficiency and power of electric vehicles.

Improved Cooling Systems

Efficient cooling systems are essential for maintaining optimal performance and extending the lifespan of electric vehicle motors. Advanced cooling technologies, such as liquid cooling systems, ensure that the motors operate within the ideal temperature range. By dissipating heat effectively, these systems prevent overheating and enhance the overall efficiency of electric vehicle motors.

Vector Control Technology

Vector control technology allows for precise control of electric vehicle motors, resulting in improved efficiency and performance. This technology enables the motors to operate at optimal speed and torque levels, reducing energy losses and maximizing power output. By utilizing vector control algorithms, electric vehicles can achieve smoother acceleration, enhanced regenerative braking, and overall improved driving dynamics.

Power Electronics

SiC and GaN Semiconductors

Silicon Carbide (SiC) and Gallium Nitride (GaN) semiconductors are paving the way for more efficient and compact power electronic systems in electric vehicles. These materials offer superior electrical properties, enabling higher power density, reduced energy losses, and increased operating frequencies. By adopting SiC and GaN semiconductors, electric vehicles can benefit from improved power efficiency and overall system performance.

Multi-Level Inverters

Multi-level inverters play a crucial role in converting the direct current (DC) from the battery into the alternating current (AC) required to drive the electric vehicle motors. These inverters utilize multiple voltage levels, allowing for smoother and more precise control of the motor output. With the ability to generate high-quality sinusoidal waveforms, multi-level inverters improve motor efficiency and reduce electrical noise.

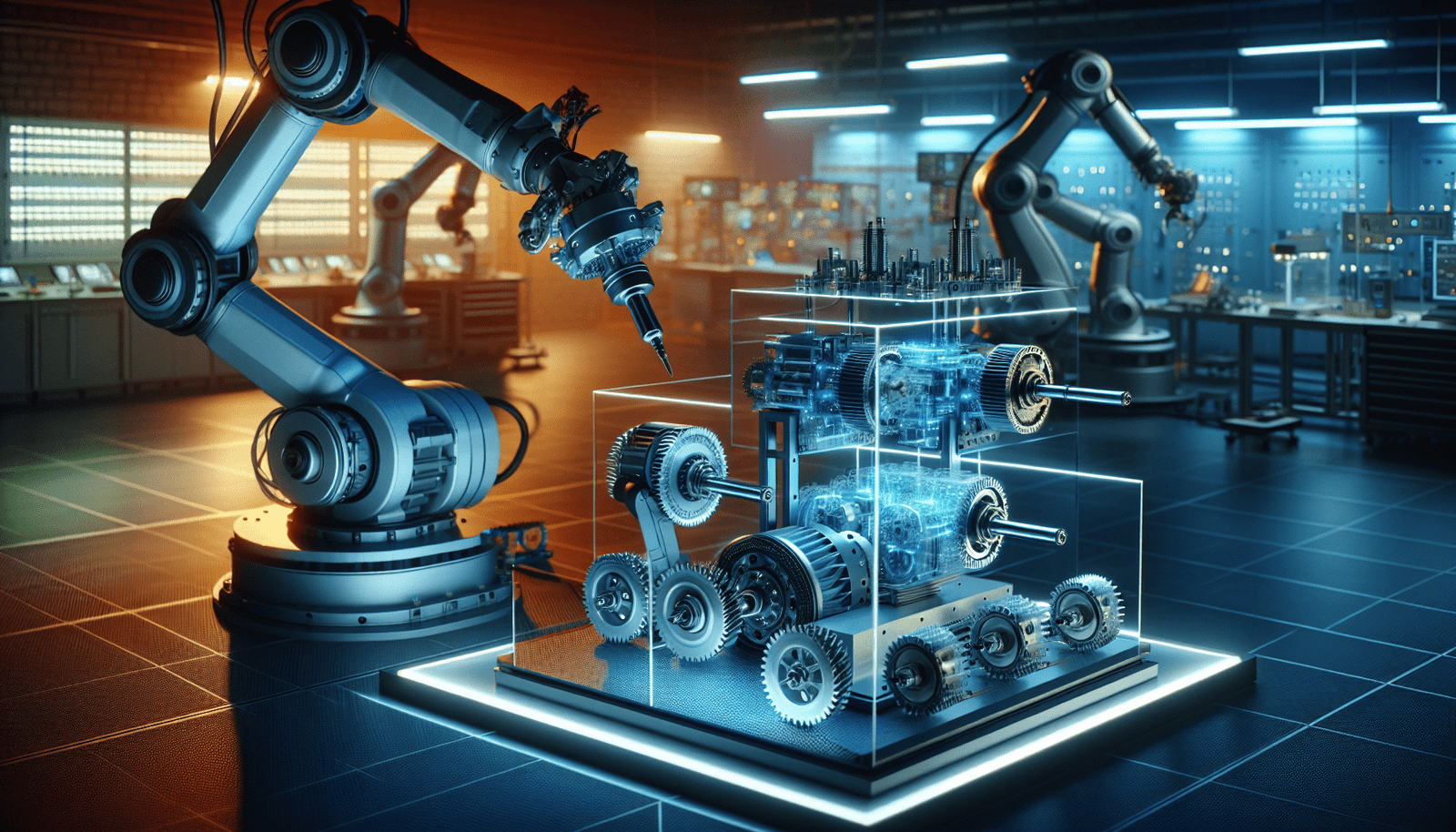

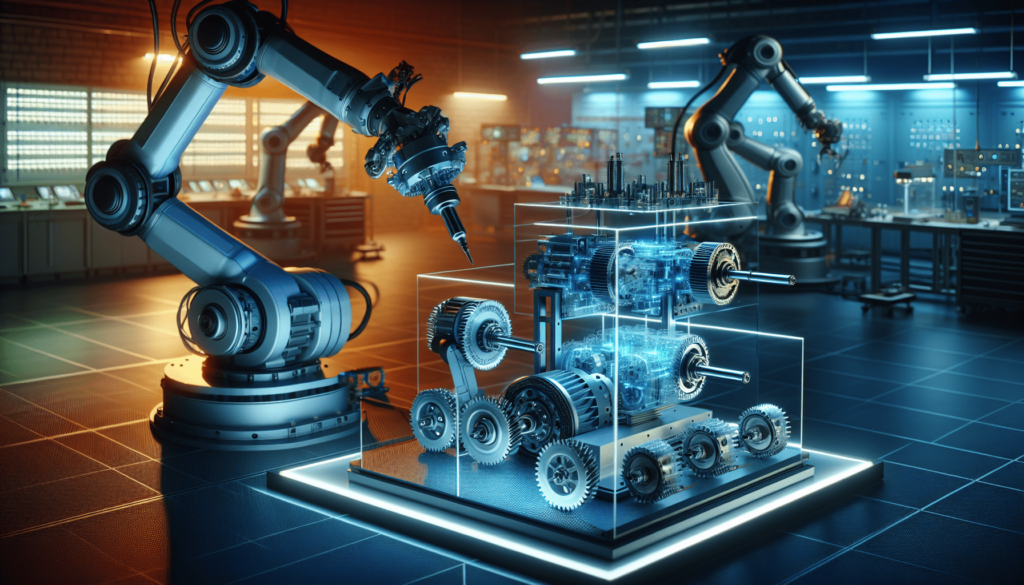

Integrated Motor Drives

Integrated motor drives combine the power electronics and motor components into a single unit. By integrating these components, electric vehicles can achieve higher power density, reduced energy losses, and improved overall system performance. Integrated motor drives simplify the vehicle’s electrical architecture, leading to lighter and more compact designs, while also enhancing efficiency and reliability.

Fast Charging Infrastructure

Fast charging infrastructure is an essential component of the electric vehicle ecosystem. By providing high-power charging stations, electric vehicle owners can conveniently recharge their vehicles in a short amount of time. Advancements in fast charging technology are focusing on increasing charging speeds and expanding the network of charging stations, enabling electric vehicles to become a viable option for long-distance travel.

Regenerative Braking

Enhanced Energy Recovery Systems

Regenerative braking systems allow electric vehicles to convert kinetic energy into electrical energy during deceleration or braking. The latest developments in regenerative braking technology aim to enhance the efficiency of energy recovery systems. By optimizing the conversion process and improving the control algorithms, electric vehicles can capture and store more energy during braking, leading to increased overall range and improved energy efficiency.

Intelligent Braking Algorithms

Intelligent braking algorithms utilize advanced sensors and control systems to optimize the braking performance of electric vehicles. These algorithms take into account various factors such as road conditions, vehicle speed, and driver input to determine the optimal amount of regenerative braking and mechanical braking required. By intelligently blending regenerative and mechanical braking forces, electric vehicles can achieve smoother deceleration, reduce wear on brake components, and maximize energy recovery.

Transmission Systems

Single-Speed Transmissions

Electric vehicles generally require fewer gears compared to internal combustion engine vehicles. Single-speed transmissions simplify the drivetrain design and reduce weight and complexity. By eliminating the need for multiple gears, electric vehicles can achieve smoother acceleration, improved efficiency, and a more seamless driving experience.

Dual-Clutch Transmissions

Dual-clutch transmissions offer faster, more efficient gear shifting compared to conventional automatic transmissions. While not as common as single-speed transmissions in electric vehicles, dual-clutch transmissions can provide the benefits of smoother acceleration and improved energy efficiency. These transmissions achieve quick gear changes through their dual-clutch design, allowing for seamless power delivery and enhanced driving dynamics.

Gearless Systems

Gearless systems, also known as direct-drive systems, offer a simplified and efficient alternative to traditional transmission systems. Instead of using gears to transfer power from the motor to the wheels, gearless systems directly connect the motor to the drivetrain. This design eliminates the need for gear shifting, resulting in reduced energy losses and improved overall efficiency. Gearless systems are particularly beneficial for electric vehicles designed for high torque and high speeds.

All-Wheel Drive

Electric Torque Vectoring

Electric torque vectoring technology allows for independent control of the torque delivered to each individual wheel in an electric vehicle. By adjusting the torque distribution based on driving conditions and traction requirements, electric torque vectoring enhances vehicle stability, cornering performance, and overall driving dynamics. This technology improves traction and maneuverability, especially in challenging road conditions, providing increased safety and control.

Independent Wheel Control

Independent wheel control systems enable precise and individual control of each wheel’s motor in an electric vehicle. By adjusting the torque and power distribution to each wheel, these systems optimize traction, stability, and handling. With the ability to independently control each wheel, electric vehicles equipped with independent wheel control systems can adapt to various road conditions, enhancing overall performance and safety.

Vehicle-to-Grid (V2G)

Bi-Directional Charging

Bi-directional charging enables electric vehicles to not only consume power but also supply power back to the electrical grid. By utilizing bi-directional charging capabilities, electric vehicles can act as energy storage devices, allowing excess energy from renewable sources to be stored in the vehicle’s battery and later discharged back to the grid when needed. This technology opens up new opportunities for vehicle-to-grid integration, enabling a more robust and sustainable energy infrastructure.

Grid Stabilization and Demand Response

Electric vehicles equipped with vehicle-to-grid technologies can play a significant role in grid stabilization and demand response. By intelligently managing energy flows between the vehicle and the grid, these systems can support peak demand periods, regulate grid frequency, and provide backup power during emergencies or blackouts. Additionally, they can facilitate load balancing and reduce the strain on the electrical grid, leading to a more stable and efficient energy system.

Artificial Intelligence and Autonomy

Enhanced Motor Control Algorithms

Artificial intelligence-driven motor control algorithms enable intelligent control of electric vehicle motors. These algorithms continuously analyze various data inputs, such as road conditions, energy consumption, and driver behavior, to optimize motor performance and efficiency. By adapting the motor control strategy in real-time, electric vehicles equipped with enhanced motor control algorithms can provide a smoother and more efficient driving experience.

Dynamic Eco-Driving Assistants

Dynamic eco-driving assistants utilize artificial intelligence and sensor technologies to provide real-time feedback and guidance to drivers. These assistants analyze driving patterns, traffic conditions, and environmental factors to suggest optimal driving behaviors that maximize energy efficiency. By promoting eco-friendly driving techniques, dynamic eco-driving assistants help drivers optimize battery range and reduce energy consumption, ultimately contributing to a more sustainable and cost-effective electric vehicle experience.

Lightweight Materials

High-Strength Alloys

High-strength alloys, such as advanced steels and aluminum alloys, offer the potential to reduce the weight of electric vehicles while maintaining structural integrity. These lightweight materials provide a high strength-to-weight ratio, allowing for lighter vehicle components without compromising safety or durability. By reducing vehicle weight, electric vehicles can achieve improved energy efficiency, longer driving ranges, and enhanced overall performance.

Carbon Fiber Reinforced Polymers

Carbon fiber reinforced polymers (CFRP) are lightweight and extremely strong materials that offer exceptional mechanical properties. By incorporating CFRP into electric vehicle components, manufacturers can significantly reduce weight while maintaining structural integrity. Although CFRP can be more expensive than traditional materials, ongoing research and developments aim to optimize production processes and reduce costs, making these materials more viable for mass production of electric vehicles.

Aluminum and Magnesium Composites

Aluminum and magnesium composites are gaining popularity in the electric vehicle industry due to their lightweight properties and favorable mechanical characteristics. These composites offer high strength, excellent corrosion resistance, and good thermal conductivity. By utilizing aluminum and magnesium composites in various vehicle components, such as body panels and structural elements, electric vehicles can achieve significant weight savings, leading to improved energy efficiency and extended driving ranges.

Wireless Communication

Vehicle-to-Vehicle (V2V) Communication

Vehicle-to-vehicle communication enables wireless communication between vehicles to exchange information regarding speed, position, and behavior. By facilitating real-time communication and situational awareness, V2V communication enhances safety on the roads. Electric vehicles equipped with V2V communication capabilities can effectively communicate with other vehicles to prevent collisions, optimize traffic flow, and improve overall road safety.

Vehicle-to-Infrastructure (V2I) Communication

Vehicle-to-infrastructure communication allows electric vehicles to communicate with roadside infrastructure, such as traffic lights and charging stations. By exchanging information about traffic conditions, available charging stations, and grid demand, V2I communication enables more efficient and intelligent routing for electric vehicles. This technology streamlines the electric vehicle charging process and ensures that charging infrastructure is effectively utilized, leading to reduced charging times and improved overall convenience for electric vehicle owners.

As technology continues to advance, electric vehicles are becoming more efficient, practical, and appealing to consumers. From advancements in battery technology and motor efficiency to the integration of artificial intelligence and the use of lightweight materials, electric vehicle motors and drivetrains are constantly evolving. These developments provide increased driving ranges, improved performance, and enhanced sustainability, paving the way for a future where electric vehicles are the norm. With ongoing research and innovation, the electric vehicle industry holds great potential for a cleaner and more sustainable transportation landscape.