When it comes to the environmental impact of electric vehicles, one question that often arises is the carbon footprint of manufacturing their batteries. Have you ever wondered just how much carbon dioxide is emitted during the production process? In this article, we will explore the carbon footprint of manufacturing electric vehicle batteries, shedding light on this crucial aspect of sustainable transportation. You’ll be amazed by the insights we uncover!

Environmental Impact of Electric Vehicle Batteries

Greenhouse Gas Emissions

Electric vehicle (EV) batteries play a crucial role in promoting a cleaner and more sustainable transportation system. However, it is important to consider the environmental impact of these batteries, specifically in terms of greenhouse gas emissions. Greenhouse gas emissions contribute to climate change and are primarily released during the production and use of vehicles.

Carbon Footprint

The carbon footprint of electric vehicle batteries refers to the total amount of carbon dioxide and other greenhouse gases emitted throughout their entire life cycle, including the extraction of raw materials, battery production, energy consumption during manufacturing, and the eventual recycling or disposal of the batteries. By understanding the carbon footprint of EV batteries, we can assess their environmental impact more effectively and identify strategies to reduce emissions.

Life Cycle Assessment of Battery Manufacturing

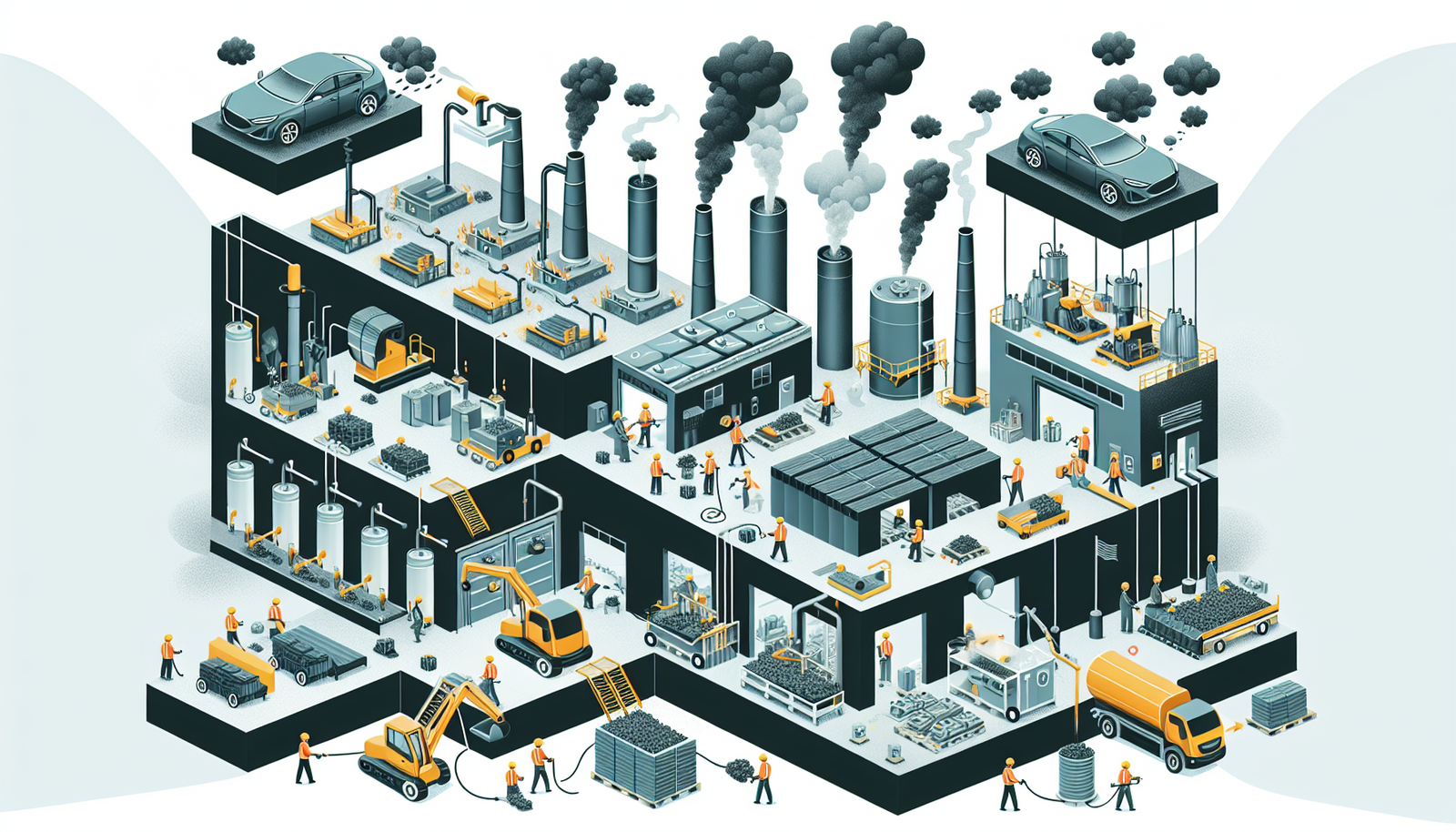

Raw Material Extraction

The first step in the life cycle of electric vehicle batteries is the extraction of raw materials. These materials, such as lithium, cobalt, nickel, and graphite, are essential for battery production. However, the extraction process can have significant environmental consequences, including deforestation, habitat destruction, and water pollution. It is vital for battery manufacturers to prioritize responsible sourcing practices and invest in sustainable mining methods to minimize the environmental impact of raw material extraction.

Battery Production Process

Once the raw materials are obtained, they go through a series of manufacturing processes to form the battery cells. These processes involve energy-intensive activities, such as chemical reactions, electrode formation, and assembly. To reduce the carbon footprint of battery production, manufacturers need to optimize their production methods, improve energy efficiency, and incorporate cleaner technologies, such as renewable energy sources.

Manufacturing Energy Consumption

Energy consumption during battery manufacturing is a significant contributor to greenhouse gas emissions. Traditional manufacturing processes heavily rely on fossil fuels, which release carbon dioxide and other pollutants into the atmosphere. However, there is a shift towards using renewable energy sources, such as solar and wind power, to minimize the environmental impact of battery manufacturing. By transitioning to cleaner energy sources, manufacturers can significantly reduce their carbon footprint and promote a more sustainable battery manufacturing industry.

Energy Sources for Battery Manufacturing

Renewable Energy

One of the most effective ways to reduce the carbon footprint of battery manufacturing is by utilizing renewable energy sources. Renewable energy, such as solar, wind, and hydroelectric power, does not emit greenhouse gases during electricity generation. By harnessing these clean energy sources, battery manufacturers can significantly reduce their carbon emissions and contribute to a greener and more sustainable future.

Fossil Fuels

Despite the advancements in renewable energy, fossil fuels still play a significant role in global energy production. Many battery manufacturers continue to rely on fossil fuels for their energy needs, which results in substantial greenhouse gas emissions. To mitigate this impact, it is essential for manufacturers to gradually transition away from fossil fuels and embrace renewable energy alternatives.

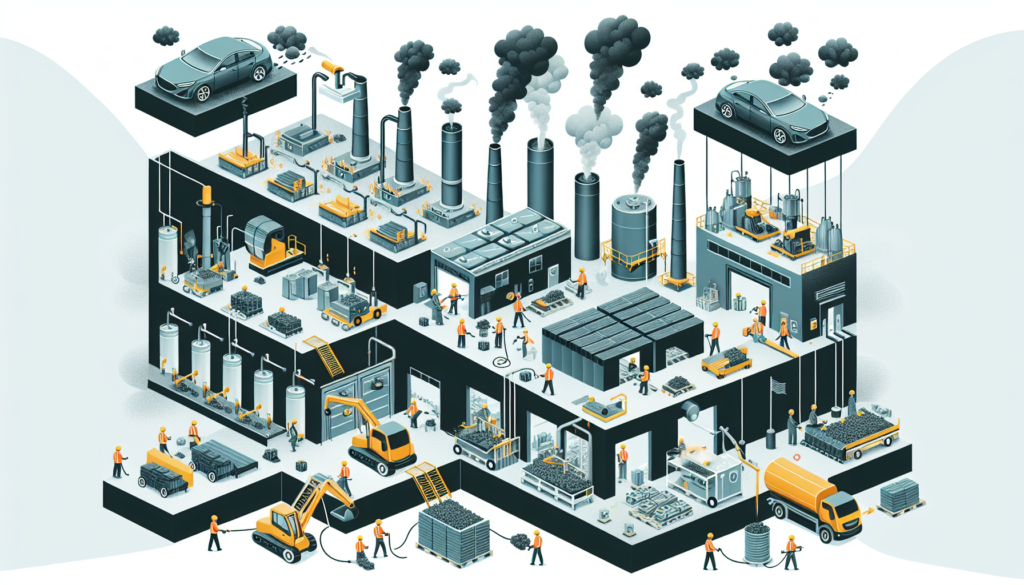

Comparing Carbon Footprint: EV Battery vs. Internal Combustion Engine

Battery Production vs. Gasoline Extraction and Refining

When comparing the carbon footprints of electric vehicle batteries and internal combustion engines, it is essential to consider the entire life cycle of both technologies. While electric vehicle batteries have higher emissions during the production phase, internal combustion engines contribute significantly to greenhouse gas emissions during the extraction and refining of gasoline. Therefore, in the long run, electric vehicles powered by battery technology have the potential to have a lower overall carbon footprint.

Battery Production vs. Vehicle Assembly

Another aspect to consider is the carbon footprint associated with vehicle assembly. Electric vehicles tend to have simpler drivetrains and require fewer components compared to internal combustion engine vehicles. As a result, the carbon emissions associated with manufacturing electric vehicles can be lower when compared to traditional vehicles. Additionally, the shift towards greener manufacturing processes can further reduce the carbon footprint of EV production.

Battery Manufacturing vs. Vehicle Operation

In terms of vehicle operation, electric vehicles produce no tailpipe emissions and have a more efficient use of energy compared to internal combustion engine vehicles. This factor significantly reduces the carbon footprint during the operational phase of electric vehicles. However, it is crucial to consider the source of electricity used to charge these vehicles. If the electricity comes from fossil fuel-based power plants, the overall carbon footprint may increase. Therefore, transitioning to renewable energy sources for electricity generation is crucial to maximize the environmental benefits of electric vehicles.

Environmental Considerations in Battery Production

Supply Chain Management

Battery manufacturing involves complex supply chains that span across various countries and regions. It is essential for battery manufacturers to prioritize sustainable supply chain practices that include responsible sourcing of raw materials and adherence to environmental and social standards. By ensuring transparency and accountability throughout the supply chain, manufacturers can minimize the environmental impact of battery production.

Recycling and Disposal

Proper recycling and disposal of electric vehicle batteries are crucial to minimize their environmental impact. These batteries contain valuable and potentially hazardous materials, such as lithium, cobalt, and nickel. When not handled correctly, these materials can pose risks to human health and the environment. Battery manufacturers should invest in robust recycling infrastructure and promote the adoption of recycling programs to maximize resource recovery and reduce the need for raw material extraction.

Future Innovations

The development of future innovations is vital to further reduce the environmental impact of battery production. Research and development efforts are focused on improving battery energy density, reducing the dependence on rare or critical materials, and exploring alternative and sustainable battery chemistries. These advancements will not only enhance the performance and affordability of electric vehicle batteries but also contribute to a more sustainable and eco-friendly manufacturing process.

Carbon Footprint Reduction Strategies

Efficiency Improvements in Battery Production

Improving energy efficiency in battery production is an effective strategy to reduce the carbon footprint. Manufacturers can implement advanced manufacturing techniques, optimize processes, and invest in innovative technologies to minimize energy consumption. By reducing the energy required for battery manufacturing, manufacturers can lower their greenhouse gas emissions and contribute to a more sustainable battery industry.

Promotion of Renewable Energy

Promoting the use of renewable energy sources is crucial to further reduce the carbon footprint of battery manufacturing. Battery manufacturers can invest in their renewable energy infrastructure, partner with renewable energy providers, or purchase renewable energy certificates. By transitioning to clean energy sources, manufacturers can align their operations with sustainability goals and become leaders in the global fight against climate change.

Development of Sustainable Materials

The development of sustainable materials for battery production is an area of intense research and development. Scientists and engineers are exploring alternative materials, such as sodium-ion batteries and solid-state batteries, that require fewer critical or rare materials while still maintaining high performance. By adopting these sustainable materials, battery manufacturers can significantly reduce their reliance on environmentally impactful materials and contribute to a more sustainable battery industry.

Conclusion

The environmental impact of electric vehicle batteries is a complex issue that requires a comprehensive understanding of their entire life cycle. From raw material extraction to battery manufacturing, energy sources, and recycling, each stage presents both challenges and opportunities to reduce the carbon footprint. By prioritizing sustainability, implementing energy-efficient practices, promoting renewable energy, and investing in future innovations, the battery manufacturing industry can play a significant role in mitigating climate change and creating a greener and cleaner future for all.