Imagine a world where our transportation is driven by clean, electric vehicles, reducing emissions and combating climate change. It sounds like a dream, doesn’t it? Well, the good news is that with the advancement of electric vehicles (EVs), this dream is becoming a reality. However, as we strive towards a sustainable future, it is crucial to understand the role recycling plays in maintaining the long-term viability of EVs. Recycling is not just a buzzword; it is a critical component of ensuring that electric vehicles remain environmentally friendly throughout their lifecycle. In this article, we will explore how recycling contributes to the sustainability of electric vehicles, shedding light on the important role it plays in minimizing waste and preserving valuable resources.

Reducing resource extraction

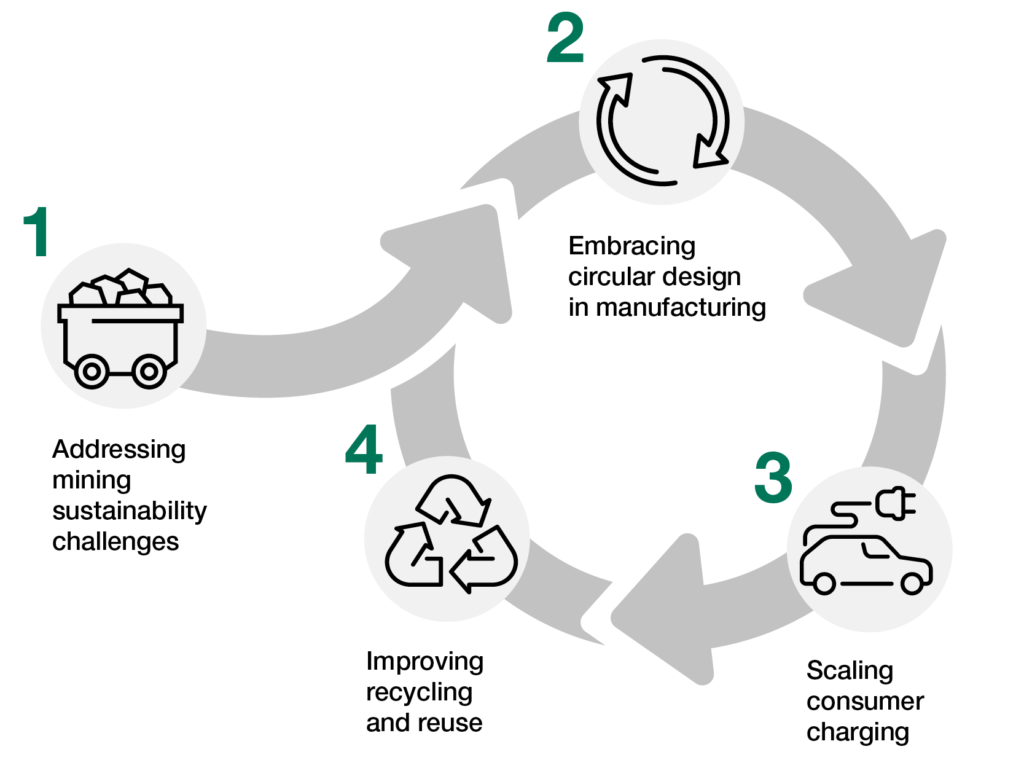

In order to promote sustainability and protect the environment, it is crucial to focus on reducing resource extraction. This can be achieved through various strategies and initiatives that aim to lower the demand for raw materials and minimize the environmental impact of mining and extraction.

Lowering demand for raw materials

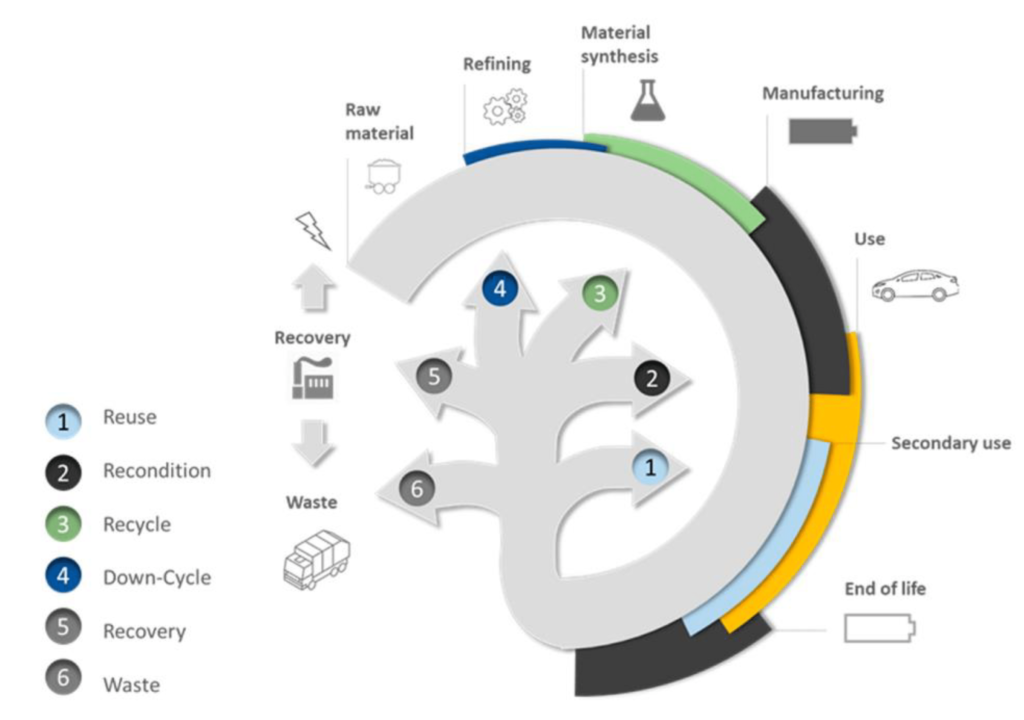

One of the key ways to reduce resource extraction is by lowering the demand for raw materials. This can be achieved through several measures such as promoting the use of recycled materials, implementing product design strategies that require fewer resources, and encouraging the development and adoption of more sustainable manufacturing processes.

By utilizing recycled materials, manufacturers can significantly reduce the need for extracting new resources from the earth. This not only helps to conserve natural resources but also minimizes the environmental impact associated with resource extraction, such as habitat destruction and water pollution.

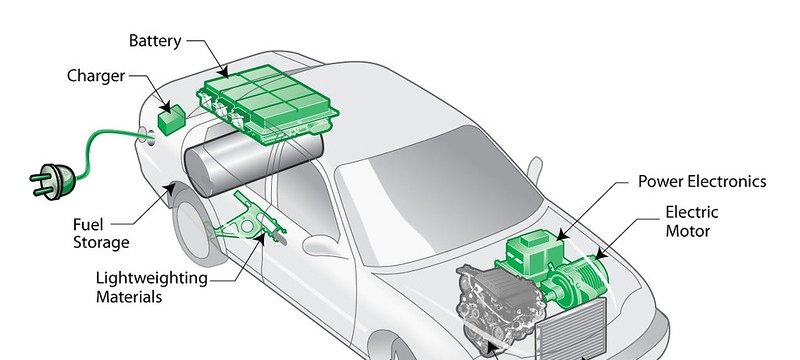

Furthermore, product design strategies that require fewer resources can also contribute to lowering the demand for raw materials. By designing products that are more efficient and lightweight, manufacturers can reduce the amount of materials needed for production. This not only reduces resource extraction but also minimizes energy consumption during manufacturing.

Minimizing environmental impact of mining and extraction

Another important aspect of reducing resource extraction is minimizing the environmental impact of mining and extraction activities. Mining and extraction processes can have significant negative effects on ecosystems, water quality, and air pollution. Therefore, it is crucial to implement measures that mitigate these impacts and promote sustainable practices.

One approach to minimizing the environmental impact of mining and extraction is through the implementation of stricter regulations and standards. By imposing stricter regulations on mining operations, governments can ensure that proper environmental safeguards are in place to protect biodiversity, water sources, and local communities.

Additionally, promoting sustainable mining practices, such as responsible land reclamation and the use of environmentally friendly extraction techniques, can help to minimize the environmental impact. These practices aim to restore ecosystems and minimize soil erosion, water pollution, and habitat destruction caused by mining activities.

Conserving energy

Conserving energy is another important aspect of promoting sustainability and reducing the environmental impact of various industries. By focusing on energy efficiency measures, manufacturers can save a significant amount of energy in manufacturing and production processes, as well as in material processing.

Energy saved in manufacturing and production

Manufacturing and production processes are often energy-intensive, requiring large amounts of electricity and fossil fuels. To conserve energy, manufacturers can adopt various energy-saving strategies and practices.

One approach is to optimize manufacturing processes to reduce energy consumption. This can be achieved by implementing advanced technologies, such as energy-efficient machinery and automation systems. For example, using energy-efficient motors and optimizing production schedules can help to reduce energy waste and improve overall energy efficiency.

Furthermore, manufacturers can also invest in renewable energy sources, such as solar or wind power, to fulfill their energy needs. This not only helps to reduce greenhouse gas emissions but also contributes to long-term energy cost savings.

Energy saved in material processing

Material processing, which includes processes like refining, smelting, and shaping raw materials, is another area where significant energy savings can be achieved. By adopting energy-efficient technologies and practices, manufacturers can reduce energy consumption during material processing and contribute to overall energy conservation.

One approach is to use innovative technologies that require less energy for material processing. For example, the development of advanced recycling technologies and novel refining processes can help to minimize energy consumption while still achieving high-quality material outputs.

Additionally, in material processing, it is important to prioritize recycling and reusing materials whenever possible. By utilizing recycled materials, manufacturers can avoid the energy-intensive processes associated with extracting and refining new raw materials. This not only conserves energy but also reduces environmental pollution and helps to create a more sustainable materials economy.

Limiting waste

The generation of waste is a significant environmental challenge that needs to be tackled to promote sustainability. By implementing strategies and practices that aim to limit waste generation, we can minimize the negative environmental impacts associated with waste disposal and landfilling.

Reducing landfill waste

One of the key objectives in limiting waste is to reduce the amount of waste sent to landfills. This can be achieved through various measures, including waste reduction at the source, increasing recycling rates, and promoting alternative waste treatment methods.

At the source, waste reduction can be achieved through product design strategies that aim to minimize the use of materials and packaging. By designing products with durability, repairability, and recyclability in mind, manufacturers can contribute to waste reduction throughout the product lifecycle.

Furthermore, increasing recycling rates is crucial in limiting landfill waste. By implementing comprehensive recycling programs and educating the public about the importance of recycling, we can divert a significant amount of waste from landfills. This not only helps to conserve resources but also reduces the environmental impact associated with waste disposal.

Preventing hazardous materials in landfills

Another important aspect of limiting waste is preventing the disposal of hazardous materials in landfills. Hazardous materials, such as certain chemicals and electronic waste, can pose serious risks to human health and the environment if not handled properly.

To prevent hazardous materials from being disposed of in landfills, it is important to implement strict regulations and standards for their proper handling and disposal. Governments should enforce laws that require the safe disposal of hazardous waste and encourage the development of specialized facilities for their treatment and recycling.

Furthermore, promoting the use of safer alternatives to hazardous materials can also contribute to waste reduction and environmental protection. By incentivizing the adoption of non-toxic and environmentally friendly materials, we can reduce the need for hazardous waste management and minimize its environmental and health impacts.